Papermakers know that working with recycled pulp is no easy task. Recycled paper mills typically struggle to achieve targeted finished product physicals, with sheet strength being one of the key issues. As a result, recycled tissue, towel, napkin and linerboard production typically requires added virgin pulp and/or chemicals to compensate. Softwood pulp, dry strength additives and wet strength additives must be added to the furnish to achieve acceptable results. These options are all costly.

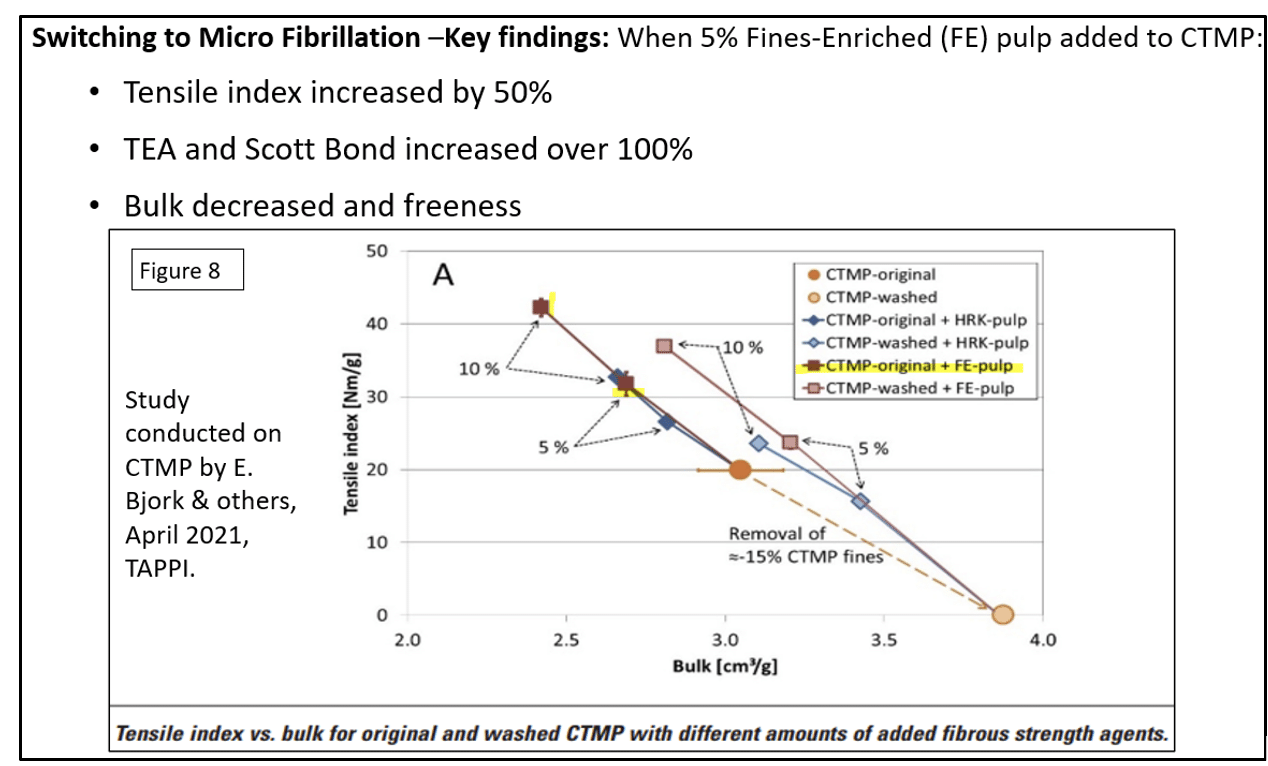

But what if you had a process that could increase strength and other properties while reducing the need for additional furnish and chemicals? That is exactly what Pulmac created with Glu-Pulp®, a patented process now under commercial development. We have already achieved some exciting results, which I shared during a presentation, “Developing Strength from Recycled Fibers using Micro Fibrillations,” at TAPPICon this past April in Atlanta, Ga. The key point of my talk was that micro fibrillation significantly increases surface area, exposing what are called crill—small, hairy fibers developed during the refining process that act like Velcro or glue to bond the fibers together, making them behave much like long fibers. This in turn dramatically increases sheet strength.

There was great interest and excitement on this topic from the audience of 50 papermaking professionals, who asked intelligent questions about the technology. In fact, of all the presentations I’ve done in my career, this was one of the top two regarding questions being generated. Audience members were particularly interested in using the increased strength to lightweight their products and sharply reduce the use of dry and wet strength chemicals additives for tissue, and cationic starches for linerboard (making them ESG friendly). Even one of our competitors talked with me afterward, asking about possibly partnering on the project.

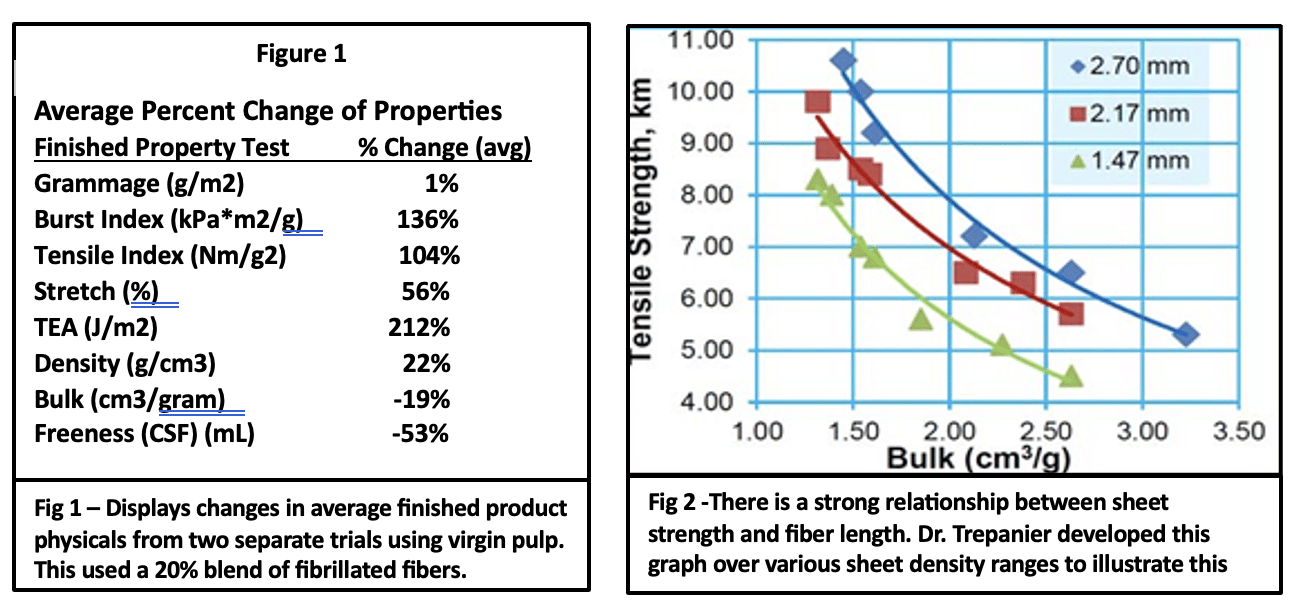

So, what is Glu-Pulp all about? It is a mechanical process we’ve developed as an alternative to traditional refining methods for both virgin and recycled pulp and reduced usage of additives. For example, where dry and wet strength additives are used in recycled pulp, they net out a maximum sheet strength gain of 25 to 30%, respectively. In lab tests and a pilot project, the Glu-Pulp® process produced strength gains of 50% and greater by enhancing the fiber properties of recycled and virgin pulp through micro fibrillation, which provides a significant increase in surface area of the fibers by exposing crill developed during the refining process. And the Glu-Pulp® process accomplishes all this while refining just a fraction of the pulp—20% of virgin fiber pulp and just 5% of recycled fiber—and reinjecting it into the furnish. It seems counterintuitive, but we found that by treating just a selective amount of the pulp, paper makers get a better end product than when the entire flow is processed, and at a much lower cost.

Tweaking the Refining Process

Let’s step back and examine where Glu-Pulp® fits in the refining process. Double-disc (DD) refiners are the workhorse of the pulping industry and perform well, especially on softwood pulp, to provide an extremely strong network of fiber-to-fiber bonds in finished products. Hardwoods are more difficult to refine and cannot withstand the same applied energy as softwood pulp. Recycled pulps face a challenge similar to hardwood pulp largely due to hornification (fibers don’t swell after the pulp is rewatered). Recycled pulps, and even dried virgin pulps, are subject to hornification when traditional refiners are used.

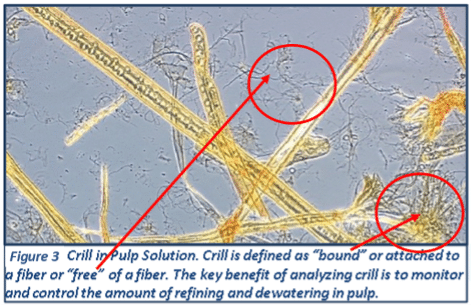

It is well known that there is a strong relationship between fiber length and increased sheet strength because longer fibers create more bonding opportunities. In strength-challenged recycled pulp with shorter fibers, crill can help increase pulp strength. Crill are hairy, thin fibers, roughly 100th the width of the fibers, and their hairy features create more surface areas that allow them to produce strong hydrogen bonds with other fibers, creating, in essence, long fiber effect that provides higher strength. The basic science is this: fibers that form a cellulose matrix are fibril bundles, which in turn consist of small elements called microfibrils. The Glu-Pulp® process opens up and frays the edges of the fibers where crill is developed. Fibers with no crill do not create much bonding. If you get the micro fibrillation process correct, many bonding sites are opened, so much so that the amount of crill is the greatest indicator of sheet strength, far greater than any other property.

The downside of this process is that too much crill reduces freeness, making sheets difficult to dewater and slowing the papermaking process. So, what can be done if some crill is beneficial and too much is not? Our solution is to take a small portion of the pulp and microfibrillate it by reducing the fiber size in the portion to 0.1 mm and below. We have demonstrated that this creates a beneficial but controlled amount of crill in virgin and recycled pulp. Further, we only use 5% of this micro-fibrillated pulp injected back into the blend chest or machine chest. When these 5% micro-fibrillated fibers with low CSF values are mixed in with the remainder of the pulp, the low CSF values are minimized when blended with the much higher CSF pulp. This ~100 CSF micro-fibrillated might take the 95% non-fibrillated pulp with a 500 mL CSF down to 450 mL while gaining 50% or more significant strength improvements.

Developing the Glu-Pulp® Process

When developing our refining process, we started by taking a subset of virgin fibers (~20% side stream), fibrillated them separately via traditional refining (macro fibrillation), and injected them back into the blend chest of OCC (old-corrugated container) pulp. This OCC trial demonstrated that macro fibrillation, which produced fibers greater than 0.1 mm in length, has its limits. We switched from a PFI beater to a high-shear, in-tank mixer in this trial. Only a modest increase was observed in tensile, TEA, and burst. Little fibrillation occurred based on no fiber reduction (e.g., no fiber cutting) or crill development. We concluded that the macro-fibrillation process was not effective for what we were trying to achieve.

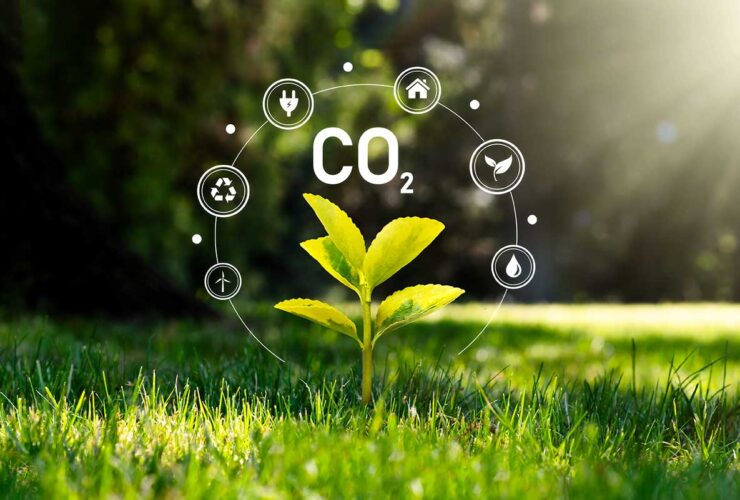

That leaves micro fibrillation to fill the gaps. A study by E. Bjork & others, published by TAPPI in April 2021, determined that a small addition (5% by volume) of micro-fibrillated, fines-enriched pulp to virgin CTMP increased tensile index by 50% and TEA and Scott Bond over 100% while decreasing bulk. Freeness was also reduced but to an acceptable level. These are extraordinary strength increases, given that traditional dry strength and wet strength additives can achieve just a 25% to 30% increase.

We developed our Glu-Pulp® process to take advantage of these demonstrated benefits. In addition to enhancing pulp properties, Glu-Pulp® is also less costly than traditional Double Disc refining. This reduces refiner energy significantly because instead of 100% of the pulp being sent to two to three DD refiners, only 5% of a side stream of pulp is needed to be refined. Surprisingly, the 5% side stream of micro-fibrillated pulp strongly outperforms the 100% refined fibers.

Another cost factor is that Glu-Pulp® will decrease the need for dry and wet strength additives and cationic starches. While exact amounts are yet to be defined, it will likely drop current dry strength and wet strength additives per ton of pulp by 50% or more.

As we continue to develop Glu-Pulp®, we expect that our micro fibrillation process will work on all recycled and virgin fibers. For example, our first pilot Glu-Pulp® project was with a large linerboard customer producing virgin pulp. We treated 20 percent of the pulp flow with Glu-Pulp® and achieved a 90% improvement in strength properties. Our customers couldn’t believe the results, so they ran the same test themselves. They returned to us and said, “It turns out you were right.”

And with recycled pulp, moving to our micro fibrillation process produces 50% to 100% gains in strength properties but drops freeness levels due to the number of fines that are developed. That is a key reason to allow a maximum of 5% of the pulp to be micro-fibrillated. More than 5% causes freeness levels to drop to 100 CSF (mL) and below. When only 5% is mixed with the remainder of the pulp, however, strength properties increase and freeness levels drop only modestly for the pulp slurry. When you can create higher strength pulps without a sharp drop in freeness, papermakers will not have to slow down their paper machines—a key demand from paper mill management.

And finally, the added strength from the Glu-Pulp® process allows papermakers to reduce the basis weight on grades, helping to lightweight their products. For example, toweling requires a machine direction (MD) tensile strength of 100 ounces per inch and a cross direction (CD) strength of 50 ounces per inch. Those strength properties typically require basis weights of 25 pounds/3,000 SF. Still, with Glu-Pulp®, papermakers can reduce basis weight to 23 pounds/ 3,000 SF, an 8% drop, while maintaining the same strength proprieties, producing substantial cost savings for the mill.

We are very excited about the prospects for our Glu-Pulp® process and are continuing to work toward commercializing it. For more information, you can contact Pulmac here and stay tuned for further blog posts!