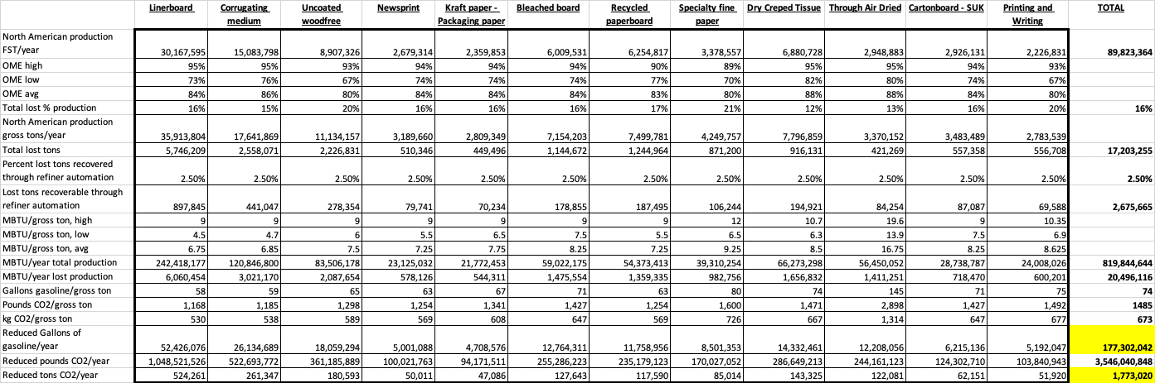

In the prior articles ( Article 1, Article 2) we showed the impact of automation in a single theoretical paper machine. To demonstrate the cumulative impact for North America, this article will use actual domestic production numbers.

Using TAPPI TIP 0404-47 “Paper machine performance guidelines”, we have Overall Equipment Effectiveness (OEE), and energy demand (Million BTU/gross ton) for each grade. This provides average OEE and energy demand figures which can be applied to North American production numbers in terms of Finished Short Tons (FST) obtained from FisherSolve. FST represents production that goes to the warehouse for shipping.

- By subtracting 100% from the average OEE values, we get an average total lost production for each grade. Overall grades, 16% of production is lost for various reasons, such as equipment not being available, slower than optimal production, and off-quality products.

- The total energy demand is calculated from the average energy demand for each grade. Different grades and paper machines, which can employ different drying techniques, can have dramatically different energy demands. Using these energy demands for the domestic production from each grade, we can calculate the total domestic energy demand for paper production of over 819 trillion BTU per year.

The table below shows that a modest 2.5% recovery of lost tons through refiner automation can reduce CO2 emission by over 1.7 million tons per year for current North American production.

*Click chart image to open an enlarged version in a new tab

Some items to note:

- Not every paper mill uses refining. In some cases, chemicals or enzymes are used instead of mechanical refining. Automation can be applied to these non-mechanical processes.

- The 2.5% savings estimated from refiner automation is a conservative estimate and will differ for each paper machine. For all grades listed above, the estimate is reasonable given that it is far below the total lost production values which average 16%.

Taken in aggregate, these ESG benefits can be dramatic. Of course, the global impact will be larger. Pulmac is a leader in helping the paper industry achieve ESG goals.

Our services and solutions are tailored to meet the diverse needs of our industry. For those who are curious to explore further or wish to dive deeper into Pulmac’s offering, simply click here to start a conversation and discover how we can assist.