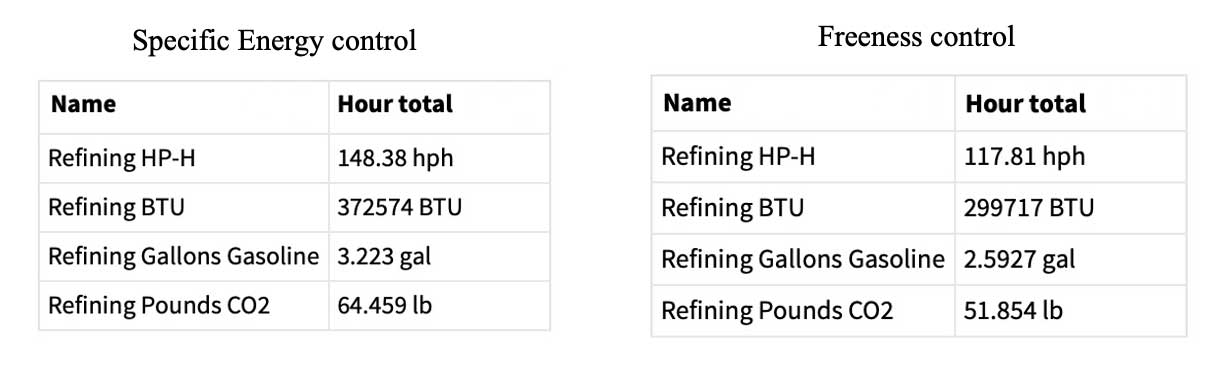

In the last article, we saw that in the hypothetical case presented, there was a significant Environmental-Social-Governance (ESG) benefit to automation of refining to freeness targets. Below are comparisons made in Seeq to show this difference in hourly energy use:

We see that Freeness control yields the following ESG benefits:

- Reduction of 53 tons CO2 per 350 operating days per year

- The equivalent reduction of 5,294 gallons of gasoline per 350 operating days per year

While these results are impressive, they are dwarfed by other ESG benefits.

In the article “Automating Pulp Refining: The Million Dollar Benefit of Measuring Freeness”, we list faster production, fewer breaks, less rejected product, and lower energy use as economic benefits. We already accounted for the lower energy use in the last article. It is difficult to find any ESG benefits to running faster since that requires more energy for increased production, so the energy per ton of product may not change. However, fewer breaks and less rejected products can be quantified in ESG terms because keeping a process running with no sellable production is wasted energy.

The article used a basis of 800 TPD production rate, with breaks per day going from 3 to 1 with break duration of 20 minutes and rejects being reduced from 16 TPD to 8 TPD. Therefore, this represents a total of 20 TPD and 54 minutes that is wasted production.

TAPPI TIP 0404-47 “Paper machine performance guidelines” provides typical “Total energy consumption” figures in Tables 4-15 for different grades. If we take the values from the “Good performance” column, for most grades this number is close to 5.0 million Btu/gross ton. This means a typical machine’s wasted energy per day is 20 Tons/day * 5.0 million BTU/gross ton = 100 million BTU. Applicable conversion factors are 115,600 BTU per gallon of gasoline and 20 pounds of CO2 produced per gallon of gasoline. This leads to the following benefits:

- Reduction of 3,028 tons CO2 per 350 operating days per year

- The equivalent reduction of 302,768 gallons of gasoline per 350 operating days per year

These numbers dwarf the benefits of reduced refining energy alone. The refining energy calculations are easy to see and provide a simple analysis. The analysis for wasted energy when there is no sellable product is more complex but shows the dramatic impact.

Therefore, when considering reduced refining energy and more efficient production, the combined ESG benefits are:

- Reduction of 3,081 tons CO2 per 350 operating days per year

- The equivalent reduction of 308,062 gallons of gasoline per 350 operating days per year

There is a tendency to focus on economic benefits and exclude other considerations. In today’s business environment, ESG needs to be a consideration. These ESG benefits can be quantified and can be dramatic. Pulmac would be happy to help you achieve your ESG goals.