How to Calculate Roll Footages / New Diameters

Have you ever been challenged with determining what a new roll diameter would be if you wanted to increase say a 200-count Bath Tissue to a 400-count? How about taking a hardwound towel from 600LF to 800LF? What if you were constrained on the Outer Diameter (OD) by a dispenser and had to determine the new footage that could be placed in a roll? This week’s article will focus on setting up these equations, then solving them.

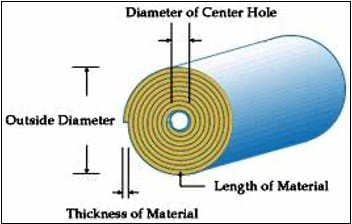

Let’s start with a review of the basic equations to be employed. First, we will use the Cross-Sectional Area of a Circle, which is PI x radius2. We immediately see that we need this in diameter, or PI x (diameter2)/4. Then we need to deal with the inner diameter, hence the equation of Cross-Sectional Area of a Circle = (PI *(OD2 – ID2))/4. Now the tricky part, how do you deal with the paper length in this equation? Recall that the area of a rectangle is length x width. Apply this same principle to a circle and the length becomes the footage and the width becomes the average wound caliper in the roll. Cross-Sectional Area of Circle = Length * thickness. Therefore, in equation form, we have:

Cross Sectional Area of a Roll = Roll Length * Average Wound Caliper = (PI * (OD2 – ID2))/4

We now have the general roll equation where we have three out of four variables, thus allowing us to solve for the fourth. We know the OD, ID, and Roll Length but not the average wound caliper. So, we solve for the average wound caliper, or thickness, of the known product and then use this same average wound caliper to solve for a new OD or new roll length. Let’s take an 8” OD product with 800 LF that you want to find what the new roll footage would be if the new dispenser being considered constrains this to say only 6.0” OD.

Setting this up, we know the existing Roll Length, existing OD & ID but not the Average Wound Caliper.

Length * Average Wound Caliper = (PI *(Outer Diameter2 – Inner Diameter2))/4

Average Wound Caliper = (PI *(Outer Diameter2 – Inner Diameter2))/ (4 * Length)

= 3.14 (8.0 in x 8.0 in – 1.8 in x 1.8 in) / (( 4 x 800 ft x 12 in / 1 ft))

= 3.14 (64.0 – 3.24) / (3200 x 12) [inches]

= 0.005 in

[Note that this is not the same caliper that you measure from QC labs with a Thwing-Albert type instrument due to the compression within the roll.]

Solving now for the new roll length that is constrained by a 6” OD roll in a cabinet:

Length (e.g. footage) = (PI *(Outer Diameter2 – Inner Diameter2))/ (4* Average Wound Caliper)

= 3.14 (6.0 in x 6.0 in – 1.8 in x 1.8 in) / (4 x 0.005 in x 12 in / 1 Ft)

= 3.14 (36.0 – 3.24) / (0.24) [FT]

= 429 LF. Would round down to 400 LF.

This general equation has numerous applications in our pulp & paper industry. Another example would be to look at parent rolls, where you know the Outer Diameter, Inner Diameter, Basis Weight, Roll Weight, Trim Width but not the Roll Length.

As discussed in a previous blog post, specifying Roll Length in the parent reel is extremely important to prevent low caliper paper going to converting. Bulk control is key. [For clarification, Bulk is the term used to describe measuring 8-plies of tissue whereas caliper is used to measure 1-ply of tissue.] Low bulk paper in turn leads to oversheeting of rolled products in converting. This oversheeting challenge affects almost every tissue manufacturer and converters worldwide. On average, this costs $2MM to $3MM annually per facility!

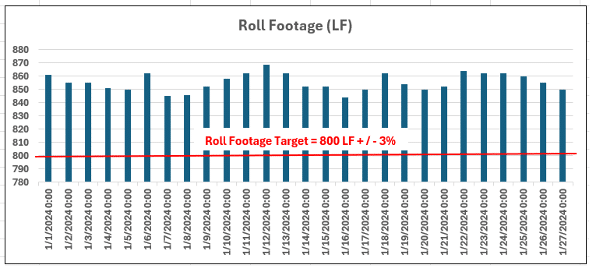

Here’s a sampling of why this is important. That “800 LF” hardwound towel (HWT) averaged ~850 LF + / – for years! QC was measuring this frequently and reporting it, but no one acted on it. That extra 50 LF of HWT was unknowingly added to each roll, costing over $2MM per year for just this one line!

What’s the key message? To monitor and control oversheeting, which typically shows up in converting through QC testing, needs resolution in the paper machine room. Controlling low bulk can be identified and controlled. Understanding the entire process, from the pulp mill, stock prep, paper machine room through converting is critical to resolving oversheeting. A key component to identifying which lines have the most oversheeting, we recommend using Advanced Analytics to automate the capture of the QC data. Many times, QC personnel write this on a piece of paper or in an Excel spreadsheet. Automating the capture of this into the rest of your management system provides a daily snapshot of the issue and progress.

I’ll address calculating the Roll Footage in parent reels in an upcoming article. Based on experience, poor bulk control from the paper machine accounts for 80% of the oversheeting that is noted by QC in converting. And 20% occurs in converting. Controlling bulk and roll footage in the PM room will reduce this $2MM to $3MM loss per year that is leaving your facility’s docks daily. Stay tuned. More to come.