- Mil A – 1754 Random samples from several Mills that use pyrometers.

- Mill B – 1418 Are we alright?

- Mill C – 1662 Calibration?

- Mill D – 1308 Impurities?

- Mill E – 2,000

- Mill F – 2,100

Emissivity is a measure of how effectively a surface emits infrared energy. For most materials, emissivity is the opposite of reflectivity.

Emissivity settings for a typical pyrometer for two materials:

- Cement 54

- Limestone 85 – 0.90

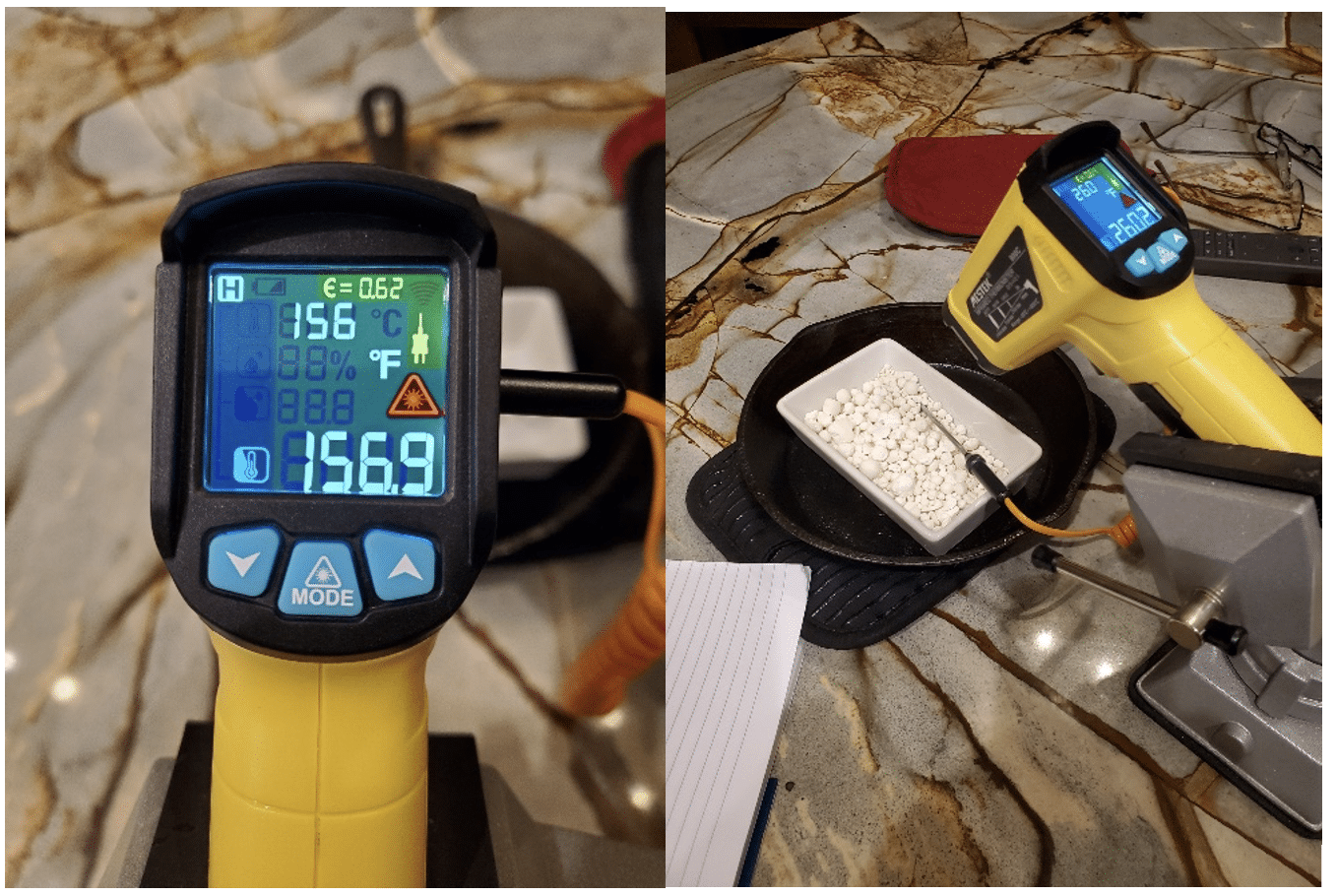

A random lime sample was obtained from a Mill that normally runs around 1700 Deg F. A simple test procedure was developed using a hand pyrometer with an integral K-type thermocouple. The same sample would be heated in an oven to 300 Deg F and at different points during sample cool down, the emissivity was adjusted to obtain the same surface temperature measured by the device’s integral K-type thermocouple.

The test results indicated an average emissivity of 0.64.

WHY? The analysis of the sample shows 99% Calcium. So, in general terms, the quality of the lime is good. So, the pyrometer must be wrong? Or is the calcium in the sample just not calcium oxide but other calcium compounds that just do not react in the causticizer system?

Below is a picture of the lime sample tested using the handheld pyrometer and the test results:

|

Pyrometer |

Thermocouple | Emissivity | Delta | |

| 156.9 | 156 | 0.62 | 0.9 | |

| 141 | 142.4 | 0.62 | -1.4 | |

| 134.8 | 134 | 0.62 | 0.8 | |

| 127 | 126.1 | 0.62 | 0.9 | |

| 165 | 164.1 | 0.62 | 0.9 | |

| 260 | 260.2 | 0.64 | -0.2 | |

| 224 | 223.7 | 0.67 | 0.3 | |

| 199 | 198.7 | 0.69 | 0.3 | |

| 165 | 165.2 | 0.64 | -0.2 | |

| 137 | 136.9 | 0.64 | 0.1 | |

| 165 | 165.2 | 0.64 | -0.2 | |

| 137 | 136.9 | 0.64 | 0.1 | |

| 131 | 130.5 | 0.64 | 0.5 | |

| 117 | 117.3 | 0.62 | -0.3 | |

| 110 | 109.6 | 0.62 | 0.4 | |

| Average | 158 | 158 | 0.64 |

0.19 |

Mills that run pyrometers to measure kiln temperature use emissivity settings between 0.9 and 1.0. A true temperature to properly convert CaCO3 to CaO is around 2100 Deg F. So, if my product emissivity is truly lower than the setting of the pyrometer, the actual temperature is higher than the reading!

An interesting point is that Mills that run a high dead load, using more lime per gallon of green liquor, would be running more dead load into the kiln which would result in a lower temperature reading if using a pyrometer to measure temperature. Another interesting point high dead load or unreactive lime is not just calcium carbonates but other calcium compounds that just did not react prior to returning to the kiln.

A way to minimize dead load is to contact Pulmac. Pulmac offers an in-line RedEye measurement system that measures the chemical makeup of your green and white liquor and allows the Mill to add the correct amount of lime with additional probes at various stages of your causticizer system. Pulmac also offers DataSolve which can work with your data in two ways. With a simple application installed on your historian to allow remote viewing of requested data that is indexed, so nothing is ever moved, copied or modified or just provide the data extracts and Pulmac uses their application to organize the data and work collaboratively with personnel to facilitate discussions and investigations while performing the analytics and providing the results.

Pulmac has elected to utilize the Seeq application for DataSolve because it addresses many of the needs of Industry 4.0 while also empowering personnel quickly to investigate, iterate on, share and act/decide on insights to drive improved production and business outcomes.

With the technical resources provided by Pulmac, reducing the dead load to the lime kiln will reduce gas uses up to 20% and provide a uniform white liquor to the digesters with lower carbonate carry-over.