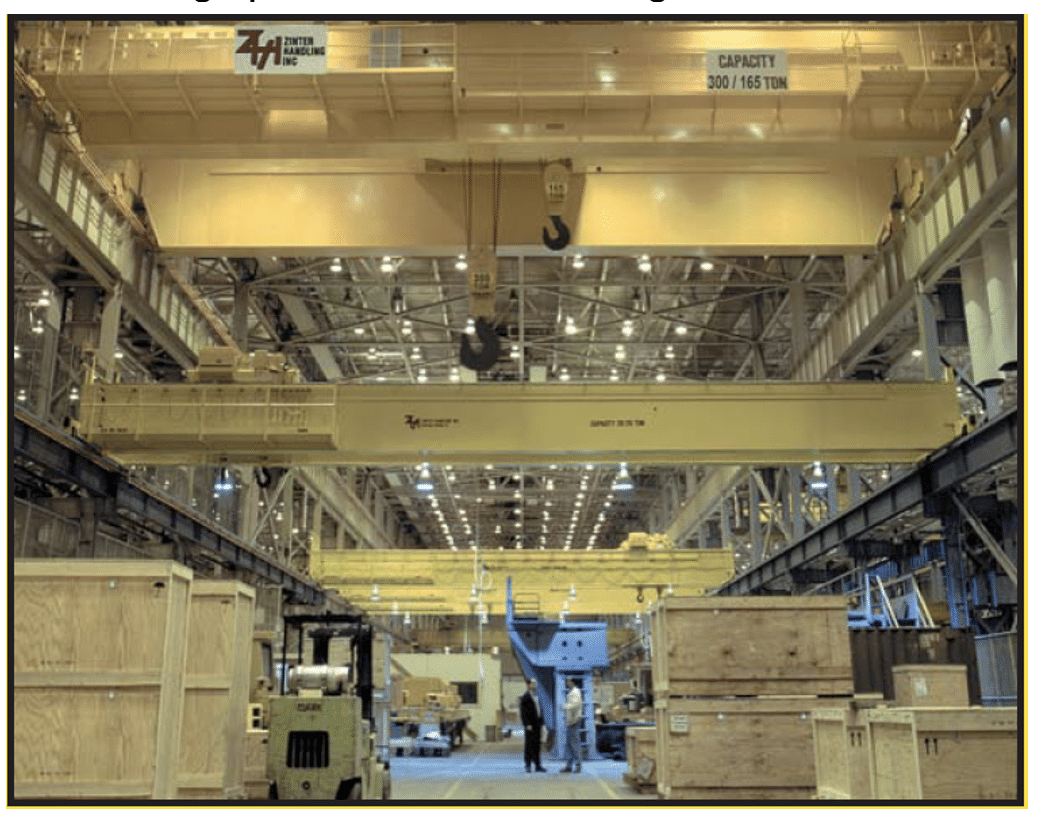

Zinter Hoists and Cranes Offer Best in Class Technology

This week’s post focuses on an important but often ignored part of Pulp & Paper operations: Our Hoists and Cranes. As with many pieces of equipment in pulp mills, paper machine rooms, and converting operations, we take for granted that our hoists and cranes will do the job.

Anti-Sway Capabilities

We often learn to live with issues on existing cranes and think that all that swinging/swaying is just natural and to be expected. So, we live with these built-in challenges of moving heavy loads such as parent rolls from the parent reel to the winder to storage and converting. However, eliminating the sway (up to 90%) can improve cycle time, make accurate load placements, increase safety, and decrease training time. Anti-sway technology is built into the control algorithms that take your best crane operators’ knowledge and skill set and creates that experience into the operator controls. This makes roll handling quick, safe, and more productive. And yes, this controls technology can be retrofitted to most controls.

Head Space Constraints

Another common challenge is that you want to increase parent roll diameters from, say, 60” to 80” OD. To make that happen, not only is the existing crane not rated for the new parent roll weight but there isn’t enough clearance. Zinter always faces this challenge and has engineered many solutions that provide numerous customers with greater weight, anti-sway, and height clearance solutions. [For those looking for a method to calculate what a new parent roll weight would be, such as moving from, say, 60” OD to 80” OD, which includes approximate new footage, roll weight, and caliper, please e-mail the writer and I’ll forward an Excel calculator developed over the years for all paper grades to calc the new parent roll weight and footage.]

Zinter has experience with these P&P challenges:

- Control retrofits

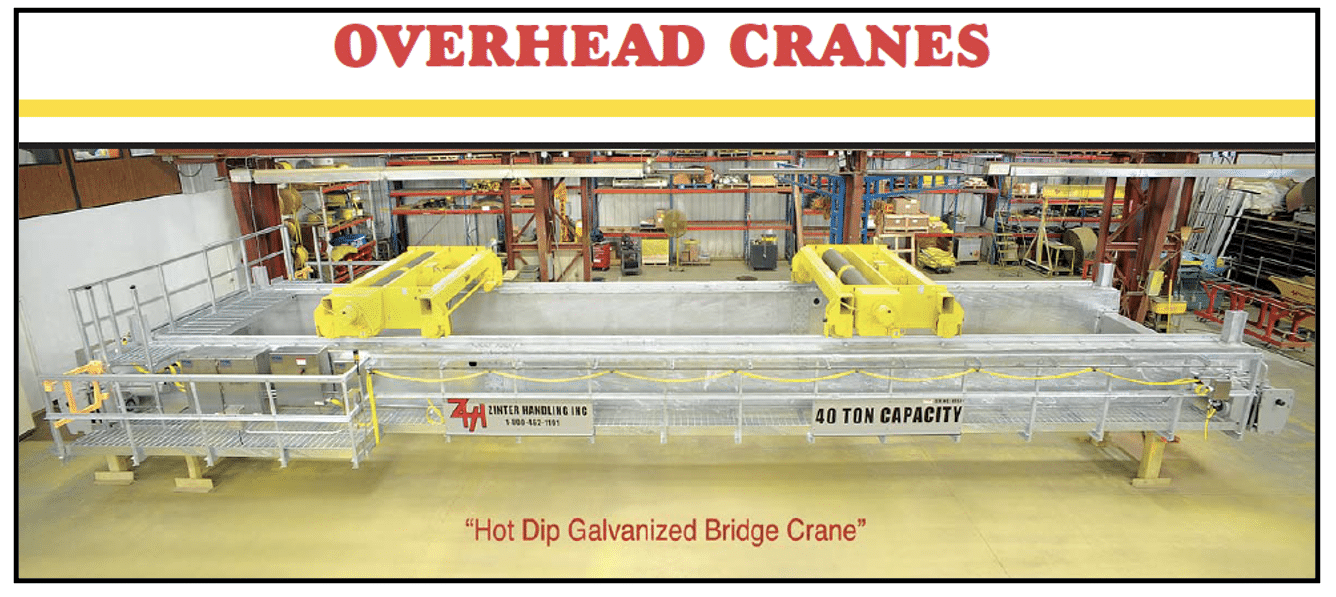

- Pulp Mill Maintenance Crane (Galvanized) and long lift tower jib type crane (Galvanized)

- Various Paper Machines, Winders, and Converting Operations across numerous mills.

- Capabilities include, but are not limited to, overhead crane systems, gantry cranes, monorails, jib cranes, hoists, load beams/spreader beams, and complete customized designs. Consulting, training, and testing services are also available.

- Numerous PMs (Wet End Crane/ Dry End Crane/ Parent Reel Cranes, and Winders)

- Low Ceiling Challenges

- Numerous overhead cranes in Converting.

To learn more about Zinter Handling or see if they can help your mill’s needs, contact Scott Zinter, President, at 800-462-1101, Ext. 213, scott.z@zinterhandling.com, https://zinterhandling.com/