In a prior article “Oversheeting in Converting: How to Recognize and Reduce Losses”, the problem of oversheeting in tissue production was explained. The article discussed engineering principles applicable to solving oversheeting. Surprisingly, oversheeting is a silent yet costly loss that leaves your facility daily by over-delivering footage / sheet count on rolled products. On average, this costs each tissue mill $2MM to $3MM per year per facility.

Modern data analytics approaches provide a powerful way to identify and to solve such problems requiring less effort. This article will explain how Pulmac’s DataSolve™ service, utilizing Seeq, provides these benefits to the oversheeting issue.

Visibility of Oversheeting

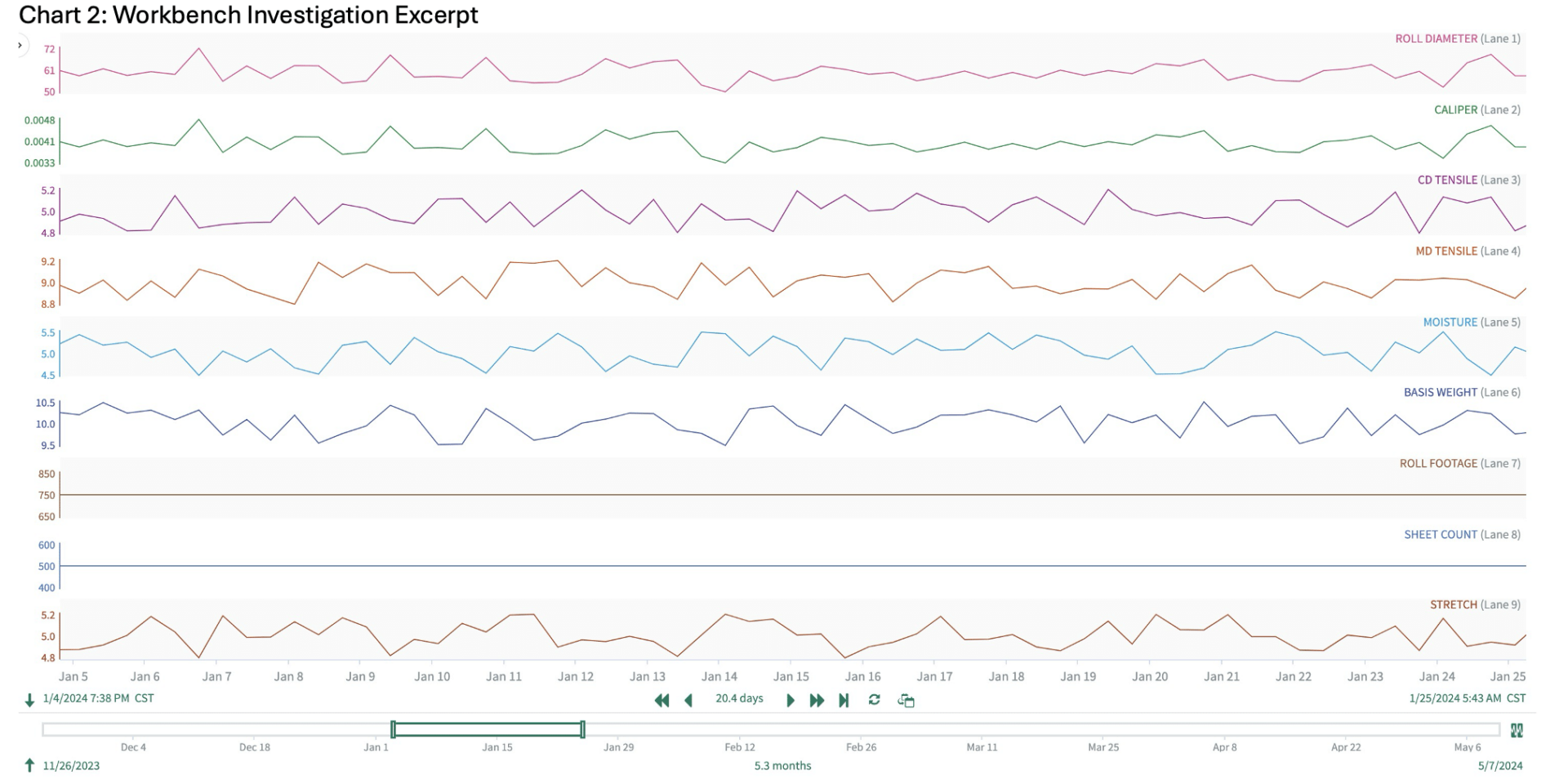

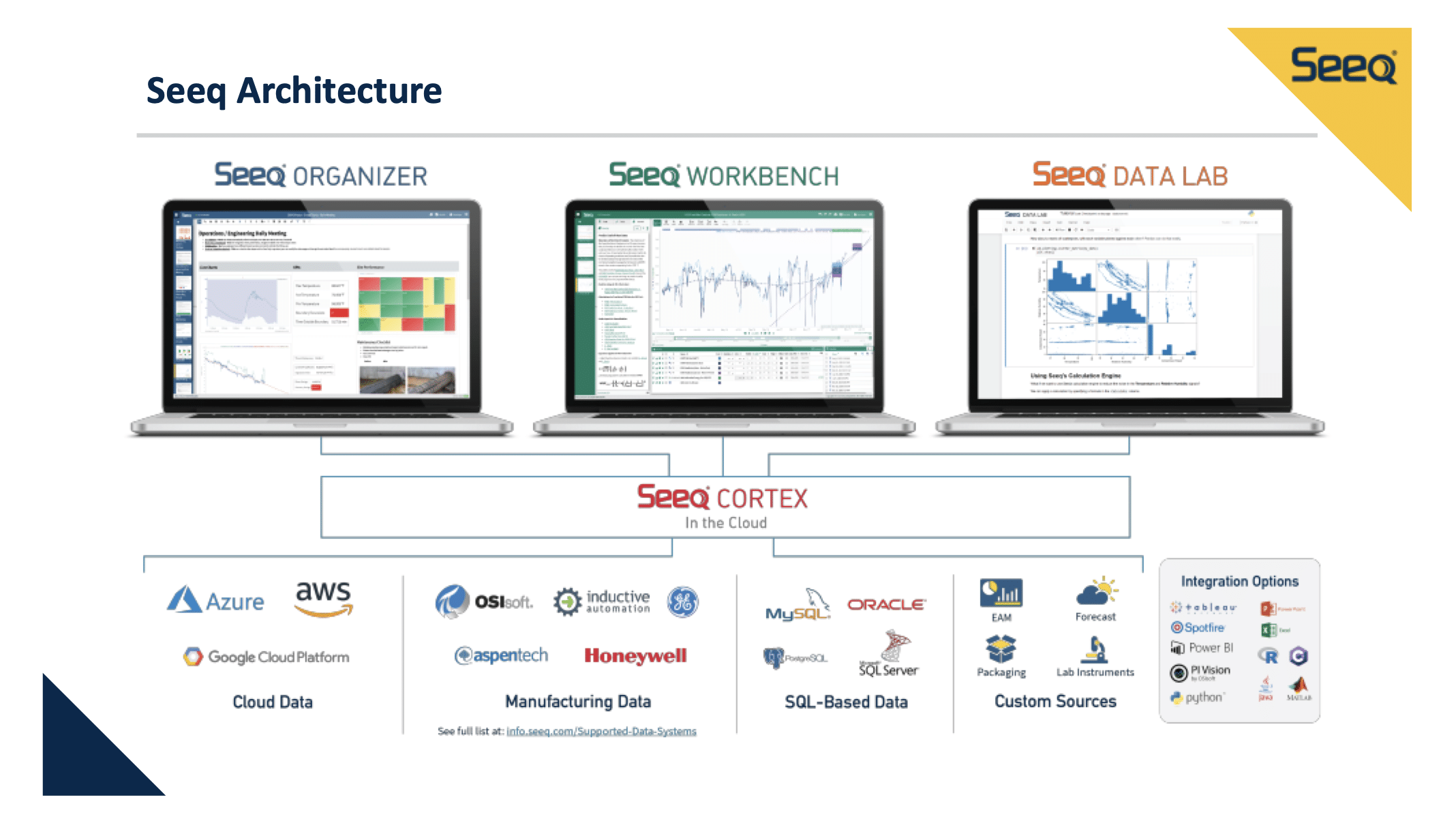

In many cases, quality control can identify oversheeting through manual testing. These results often reside in a data silo such as an Excel spreadsheet or a database that is not visible to the enterprise. Unlike low strength or low basis weight specs, high roll footage often passes QC inspection. The ability of Seeq to connect to a comprehensive list of process data sources, such as historians and databases, makes it an ideal environment for examining the consistency of your data’s “story” across systems by using Organizer to improve millwide, or enterprise, visibility. Integrating quality control results to customized dashboards elevates the situation to the attention of decision-makers that need to see it.

Analysis of Quality

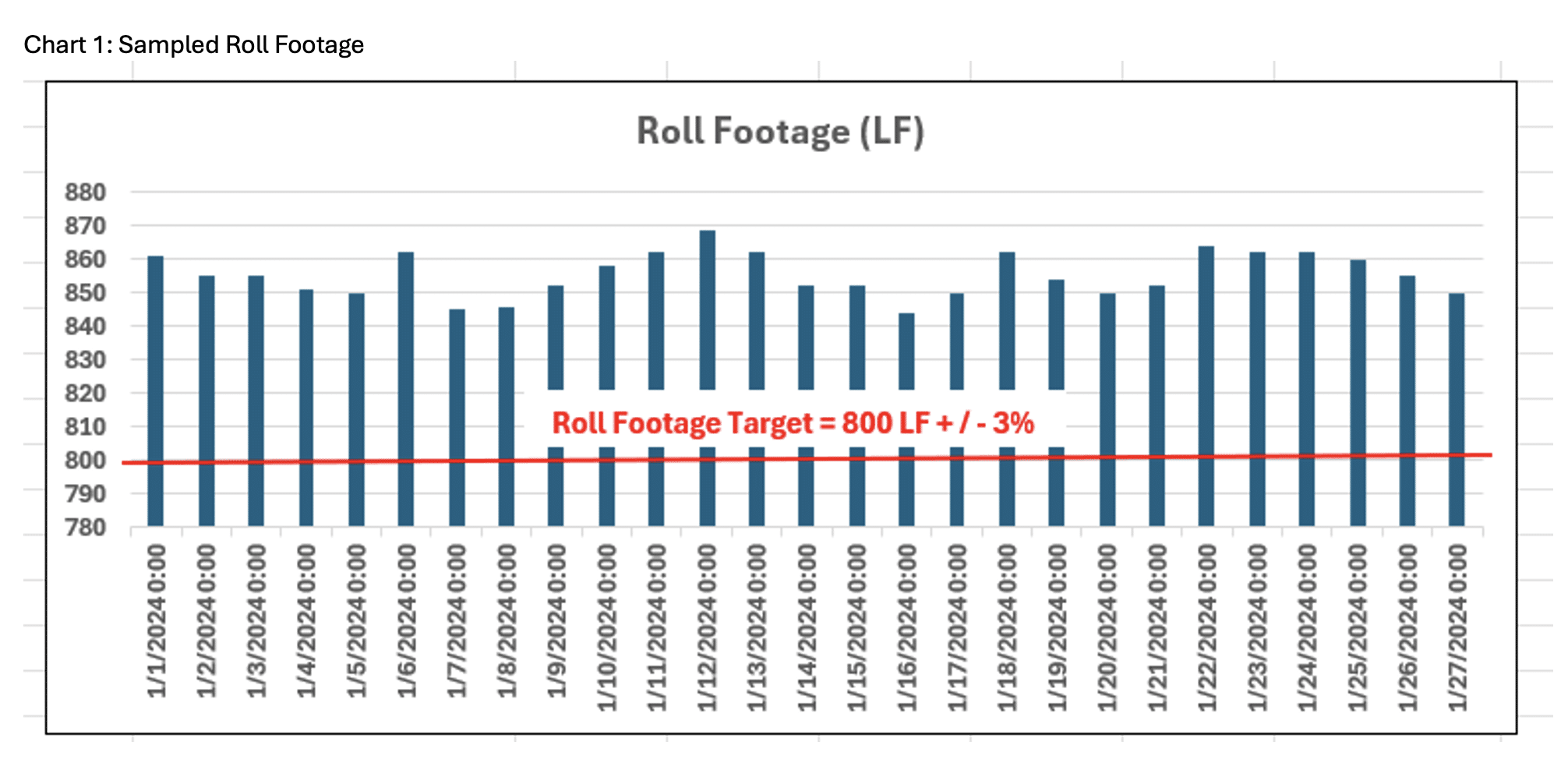

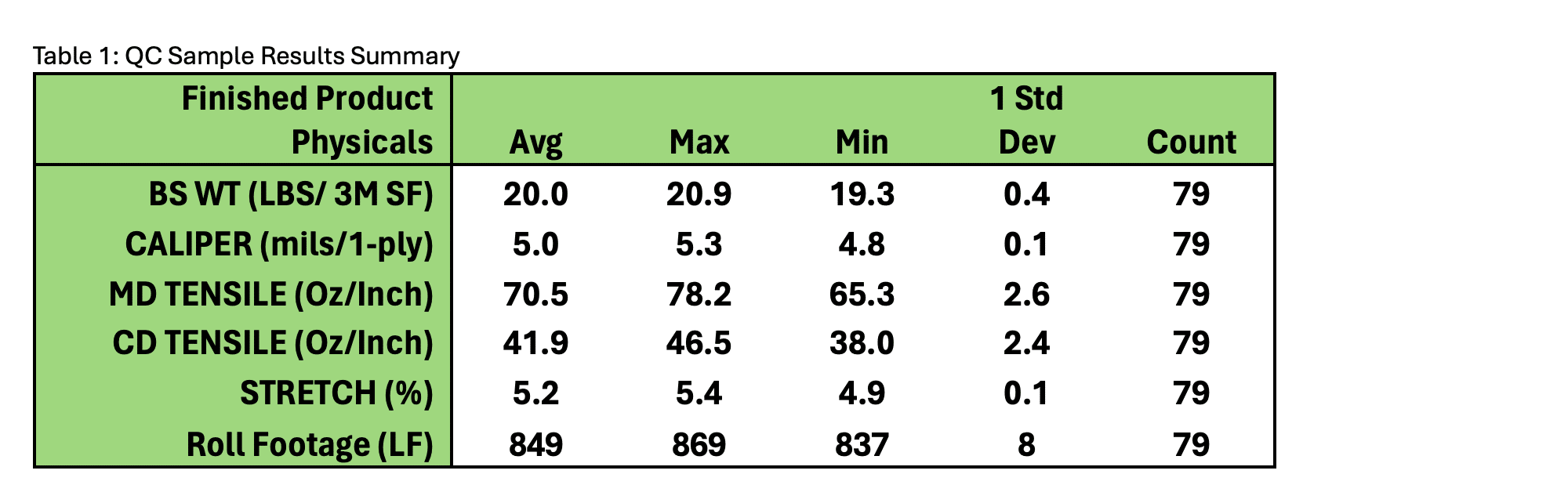

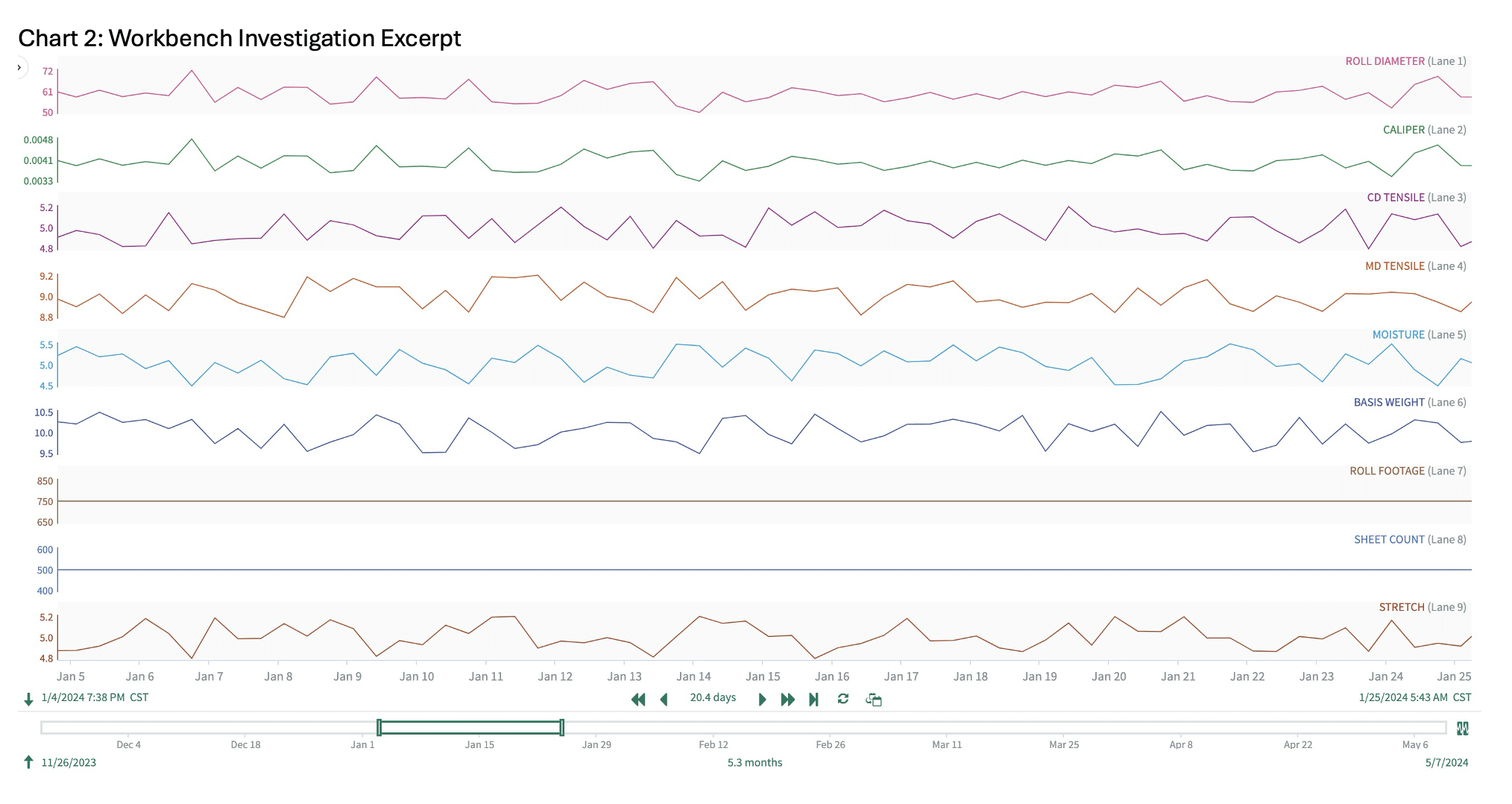

In other cases, the converting operation has a measure of linear feet of product. While this prevents oversheeting, it does not address quality concerns when caliper changes result in packaging problems. Identifying these problems requires integrated data analysis with the inclusion of quality data such as basis weight, tensile strength, stretch, caliper, moisture, and others.

Seeq Workbench can integrate all this data and apply powerful data cleansing and analysis features to find correlations to packaging problems.

DataSolve™ Is The Solution

Pulmac’s expertise in tissue, furnish quality, and analytics combined with Seeq’s capabilities yield our service, DataSolve™. DataSolve™ is our ability to be your data analytics partner to solve difficult problems while you maintain focus on running your business.

We recognize that it is a hard pill to swallow that your facility likely is oversheeting on rolled products, affecting equally Retail Bath and Towel as well as Away from Home. In our TAPPICon 2024 presentation, Resolving Oversheeting in Tissue Converting, most facilities certainly are hard-pressed to understand why this occurs and the steps needed to quantify which SKUs are the worst offenders; but more importantly, how to resolve the issue. It requires not just reviewing the converting lines and winder (when used); but it also requires an awareness of the fiber mix, refining practices, and machine settings.

Using Seeq is a great starting point to quantify where to prioritize your efforts, and the Pulmac team provides technical expertise and know-how to reduce and eliminate effectively this oversheeting issue.

Dave’s Presentation – Resolving Oversheeting in Tissue Converting TAPPICon 2024

Due to tissue products inherent high stretch, tissue is the most compressible of all paper products. Further, few mills recognize that oversheeting is occurring in converting. In most mills, it is common to see oversheeting costing between $2MM to $3MM per facility.

This presentation will provide best practices on methods to monitor and control this within your process across pulping, paper machines, winders, and converting.

About Seeq

Seeq is the premier data analytics solution for industrial process data. It offers a full-featured Workbench for data pre-processing and analysis designed for time series data, Organizer for easy and powerful visualizations to share insights, and Data Lab to extend capabilities through custom Python scripting and powerful libraries to enable scaling analytics efficiently.