What is NIR?

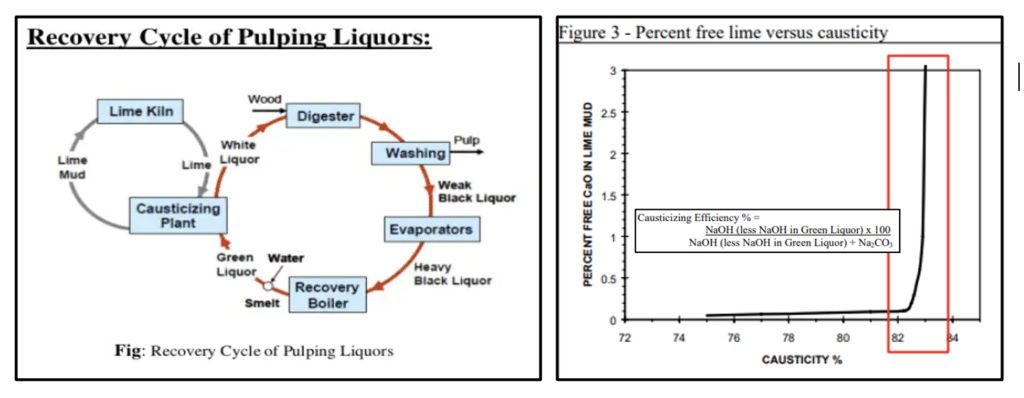

As we know, chemicals used to break down and remove lignin (i.e., the glue that holds the wood fibers together) is highly caustic. Near Infrared technology (NIR) helps you control the complexities of the chemicals interacting with the wood or non-wood species in the liquor cycle.

The 1980s Brought Mid-Infrared

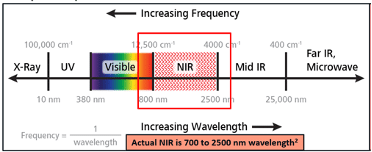

Many had used older technologies like mid-infrared (the mid-1980s, as noted below, Mid IR) to analyze the white liquor in the digesters, black liquor in the brown stock washing – recovery boiler, to the green liquor in the lime kiln recovery area.

In practice, Mid IR required a half-time field E&I tech to clean the mid-infrared sensors daily of scaling / plugging issues to correctly read how well each chemical was working. The best available technology to “see” inside each pulping process is Near Infrared (NIR).

Yet even with mid-infrared, there are a lot of variables that occur. The most common are:

- Variability in wood chip sizes (too large causes incomplete cooking, and too small causes overcooking)

- Debris entering digesters such as bark, sand, rocks, and dirt.

- Old logs due to wildfires or beetles attacking forests create unique challenges due to how these chips cook in the pulping cycle.

Each of these can cause significant upsets in pulping and bleaching plants. And what every paper maker dreads: sour pulp.

Updated Wavelength

NIR has a wavelength of 700 to 2500 nm. Mid Infrared used a higher frequency and was initially chosen to read through the highly caustic liquors, as it is more data-rich than NIR.

What are the benefits of NIR Technology?

NIR technology offers the ability to act like having X-ray vision into your pulping process.

Although the liquor cycle of P&P is considered the most complex and dangerous within our industry, NIR technology offers an unparalleled capability to monitor, measure, and control the chemical reactions (i.e., Effective Alkali, Active Alkali, Residual Alkali, and Total Titratable), and adjust as needed for each liquor cycle.

This provides:

- real-time processing

- is a non-destructive measurement

- no titration solution is needed

- does so without plugging

The long-term value

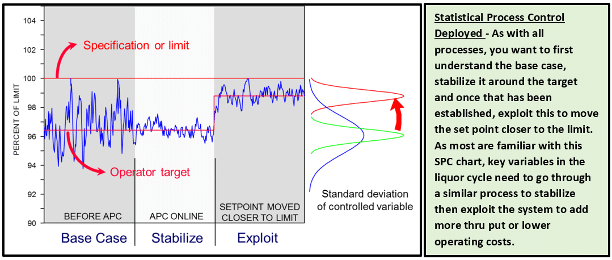

Most of these systems are purchased to avoid significant upsets in the liquor cycle. But once the major upsets are under control, the real benefit is reducing variability in your pulping process. This, in turn, allows all downstream processes to run very well, day in and day out. That lowers chemical consumption, increases operating efficiency, and allows your mill personnel to tackle projects instead of constant firefighting.

How is NIR used?

As noted above, there are a lot of variables that can occur in the liquor cycle. During my PEERS presentation (download it here), seeing it was Halloween season, I tried to use an analogy of two candy bars. I held up a Snickers and a Reese’s Peanut Butter Cup. We all know the difference between these two candy bars and think of these as different chemicals being analyzed. The NIR sensors can read the different chemicals and strength (think magnitude) of each. In the candy bar example, a large Snickers bar vs. a Fun size Snickers bar provides the magnitude of each chemical and its interaction with the different-sized wood chips or debris present.

Using the NIR Sensors from PulpEye’s RedEye technology, it can immediately identify an incomplete chemical reaction and adjust the dosage to keep the process within process limits. For NIR technology to work correctly, a Fourier Transformation is needed to discern the vibrating frequency of each chemical present and its magnitude.

Example

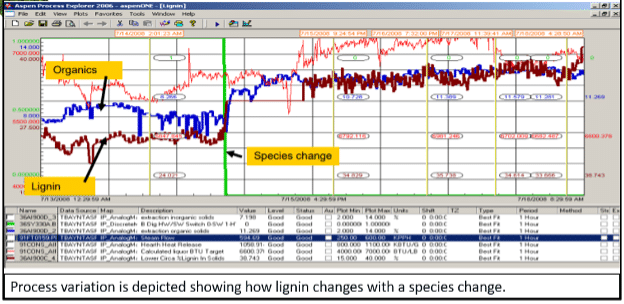

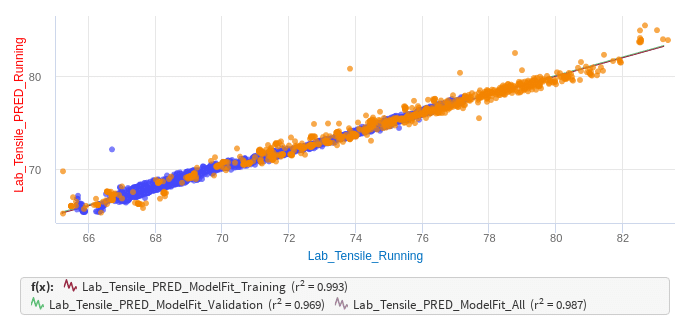

In the graph noted below, there was a change in tree species. This was treated as a grade change, where more chemicals were consumed to keep the process steady.

Who uses NIR and Adoption Rate?

Most P&P mills in North America were built in the 1970s and 1980s, some 40 to 50 years ago. This technology was not commercialized when most pulp and paper facilities were placed into production. Early systems used Mid IR and, as noted, caused considerable scaling and plugging issues. When NIR technology was introduced in the mid – 1990’s, there was skepticism due to Mid IR issues, and as with most new technologies, NIR was slow to be adopted.

This technology is now widely accepted throughout the P&P industry. Adoption varies based on success at a given mill, where cost benefits can be quantified.

When Used in Integrated Mills

For integrated mills, this NIR technology is excellent at preventing major upsets and is equally capable of reducing variability in the pulp mill. That, in turn, dramatically reduces breaks in the paper machine room.

Small facilities, including mills running miscanthus, wheat straw, and bagasse, can help stabilize their pulping process caused by the sand, dirt, and rocks entering the pulp mill. Reducing or eliminating debris is critically essential, but once this debris has been introduced, NIR can determine what chemical reactions aren’t occurring and can compensate dosage to reduce the variations that debris or wood chip quality can cause.

The Key to Minimizing the Few Challenges With NIR

Surprisingly, a few issues are noted once NIR systems are installed and debugged. Not to downplay the importance of addressing the significant process variations that can occur early on, once a steady state is achieved where the variables are understood and addressed, NIR users then turn their attention to other concerns such as shives or reducing grade change-over times. And as the pulp market tightens, customers become far more discerning regarding variations in pulp quality.

How do you minimize problems?

An effective way to minimize or eliminate NIR problems is to couple it with a PulpEye.

We have seen tremendous success when market pulp producers utilize PulpEye’s technology to control their pulping process with great precision and document the quality of each batch. – Dave, VP of R&D

For example, PulpEye’s shive and dirt modules read shives and dirt in the pulp slurry. This allows the operator to deal with dirt and shives before it hits the paper machines.

The value of a PulpEye system comes into play by allowing a mill to start small and then add modules over time to address other needs. As noted, shives are one, freeness measurements are another, fiber length and width are another, and to the discerning pulp customer, crill.

Crill is the hairy little fibers that are a by-product of refining and greatly enhance fiber-to-fiber bonding. Moreover, through online controls, a PulpEye Pulp-on-Target can accurately predict what finished product physicals will come off a paper machine from the pulp slurry! With over 400 variables that can be tracked and controlled, PulpEye’s capabilities offer unmatched processing and controls throughout a pulp and bleaching mill’s pulp and bleaching stages.

With NIR, once you understand the output available from a PulpEye, you can work proactively with Purchasing and Wood suppliers on issues. As we saw in the graph above, a process engineer provides tools to pinpoint supply issues on a wood species change. Or it can be used to understand old wood sitting in the wood yard and immediately identified as problem wood. Further, we know that trees harvested in the Spring pulp differ from Summer-Fall trees of the same species. Knowing these seasonal changes and other PulpEye capabilities can make your pulping team world-class.

Causticizing Efficiency

As discussed in my PEERS presentation, a quick tell-tale sign of how well your pulping system works is in the final liquor stage, called green liquor.

This takes the output from the recovery boiler and then runs this through the causticizing plant. This changes the green liquor into white liquor by adding lime to the lime kiln.

In most mills, a key variable that alerts management about how well the whole liquor cycle is running is the Causticizing Efficiency (CE%) percentage. Absolute max CE is 82% to 83%. Most mills run around 75%, and an exceptionally well-run mill might be in the 80%+ range.

If the first two liquor cycles of White and Black Liquor are not running well, you can’t achieve a high CE, hence the idea of using CE as a proxy to understand how well the pulp mill is running.

Let’s Talk

Give us a call for a free estimate. Let us review your needs to see if we can provide solutions to improve your bottom line with these cutting-edge, world-class technologies. We can help drive down your operating costs and prevent significant process upsets caused by the variabilities in the process mentioned above.