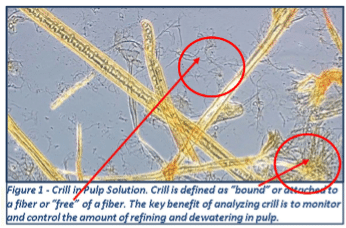

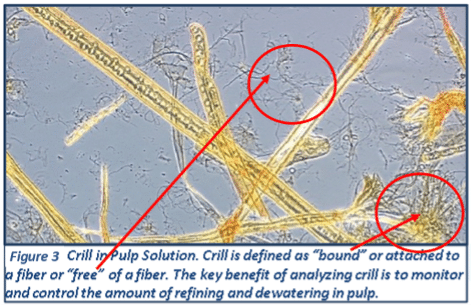

As a continuation of the discussion of crill, this use case of a hypothetical example to show how automation of crill can yield new grades at dramatically lower production cost and likely higher market value.

In our last use case “Automate with Crill”, we explained how crill measurement can be incorporated into predictive models used in automatic control. It gets much more interesting considering that Pulmac has a patented process called Glu-Pulp® that generates crill.

In our last use case “Automate with Crill”, we explained how crill measurement can be incorporated into predictive models used in automatic control. It gets much more interesting considering that Pulmac has a patented process called Glu-Pulp® that generates crill.

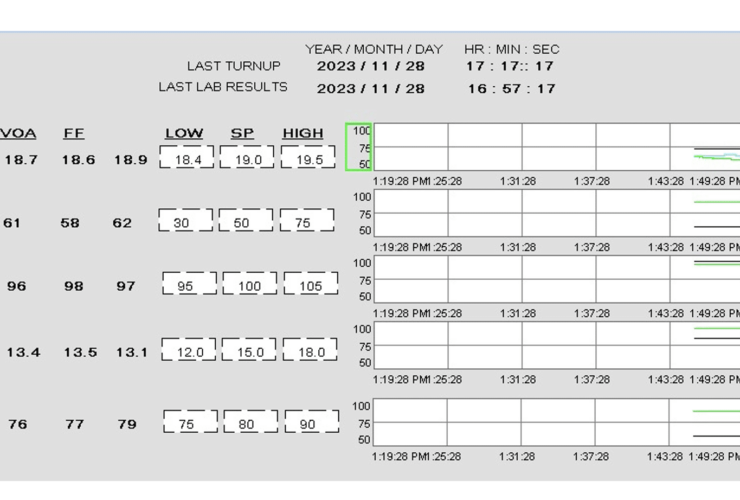

Measuring crill is not sufficient to control it. What setpoint would you use for crill? It is not a measurement with a specific target. In order to generate it, we need to know not only what crill target to use but also how much of the crill-modified fiber to blend into the furnish going to the headbox.

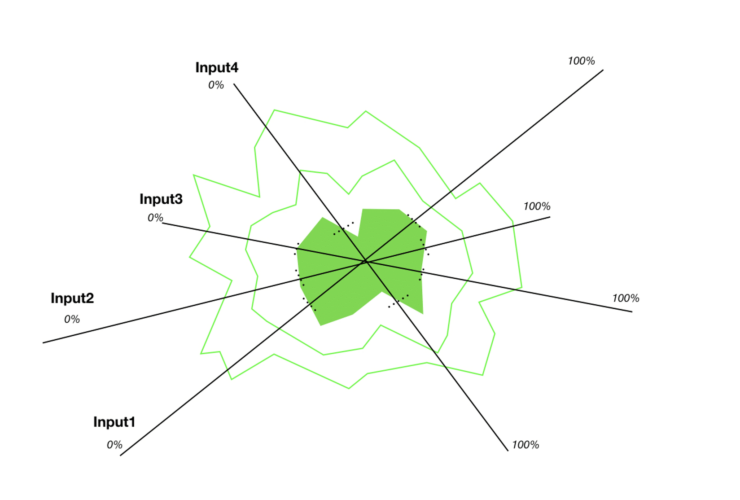

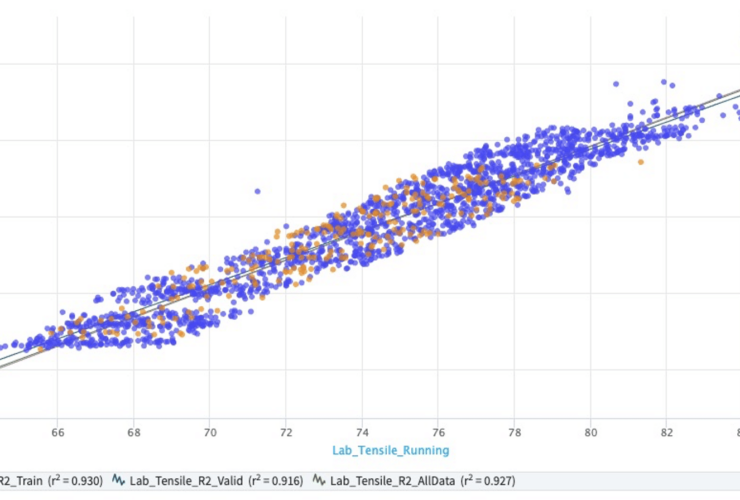

As explained in the last use case, predictive models establish the relationship of crill to quality and operating conditions. For example, a higher crill can decrease freeness and increase compactness in the sheet, which might impair drainage on the wire. However, the strength improvements from increased relative bonding area can make it possible to produce new grades at lower basis weights with high strength. These models can yield the crill targets and blend ratios to be used in automation.

Consider a hypothetical linerboard machine making 1,000 tons/day. We will use unbleached softwood in an integrated mill at a cost of $450/ton as the furnish that we will treat to make Glu-Pulp. From TAPPI Tip 0404-47, good performance would use 4.5 million BTU/gross ton. Imagine a 69 lb/ream grade that can be modified with crill addition to 64 lb/ream with the same strength properties. In the prior use case, we constrained this basis weight shift to a target allowable for the current grade, but here we are making a new grade because we can control our crill addition maintain our quality targets. This 5 lb (7.2%) drop is a dramatic savings in raw materials and energy usage. However, since we have to factor the adverse effect on drainage, the impact will be a little less. In laboratory testing, replacing 5% of the virgin fiber with Glu-Pulp® can maintain the strength targets at a 7.2% drop in basis weight. An automated solution with online optimization can adjust this fraction to determine the best Glu-Pulp® addition setpoint. If an entire production day ran this grade, it would reduce the gross tonnage by 7.2%, which would be 72 tons/day. The energy savings is 324 million BTU/day. Paper machines typically have energy costs of $0.0067/ million BTU, which would be a savings of $2,171/day on this grade. The fiber savings on unbleached softwood at $450/ton would be $32,400. Therefore, we have a grade at a lower weight that costs $37.25/ton less to make, which would be $34,571/day. This can amount to significant cumulative savings over the course of a year.

However, consider this grade might be a higher valued product. For packaging, a lighter weight reduces shipping costs. Therefore, if the market demand drives up price, the margin grows even bigger.

Let Pulmac be your partner to create new grades with the automation to maintain quality and optimal economic benefit.