Pulmac, RCM2™, and Seeq have come together to bring you industry-defining preventative maintenance services to keep your mill running at peak performance.

About RCM2™

At Strategic Maintenance Reliability RCM2™ our team will refine and optimize your current Preventive Maintenance program to incorporate industry best practices in the areas of equipment criticality, failure mode and effects methodology, EMP to PM/PdM procedure reconciliation, and safety and craft skill utilization and application.

RCM2™

Optimize your capabilities

The staffing at today’s mills is stretched thin on time and rapidly losing subject matter expertise related to maintenance and reliability (M&R). Pulmac’s innovative solutions, DataSolve™ for M&R, are closing this gap.

Partnering with SEEQ for fast data analytics and Jay Shellogg utilizing the methods of Reliability Centered Maintenance (RCM2™), our industry experts can quickly analyze your operating context and rapidly deploy an RCM2™ solution like never before.

Through the use of RCM2™ and the SEEQ AI assistant, DataSolve™ for M&R can provide Supervised AI Learning for your specific operation.

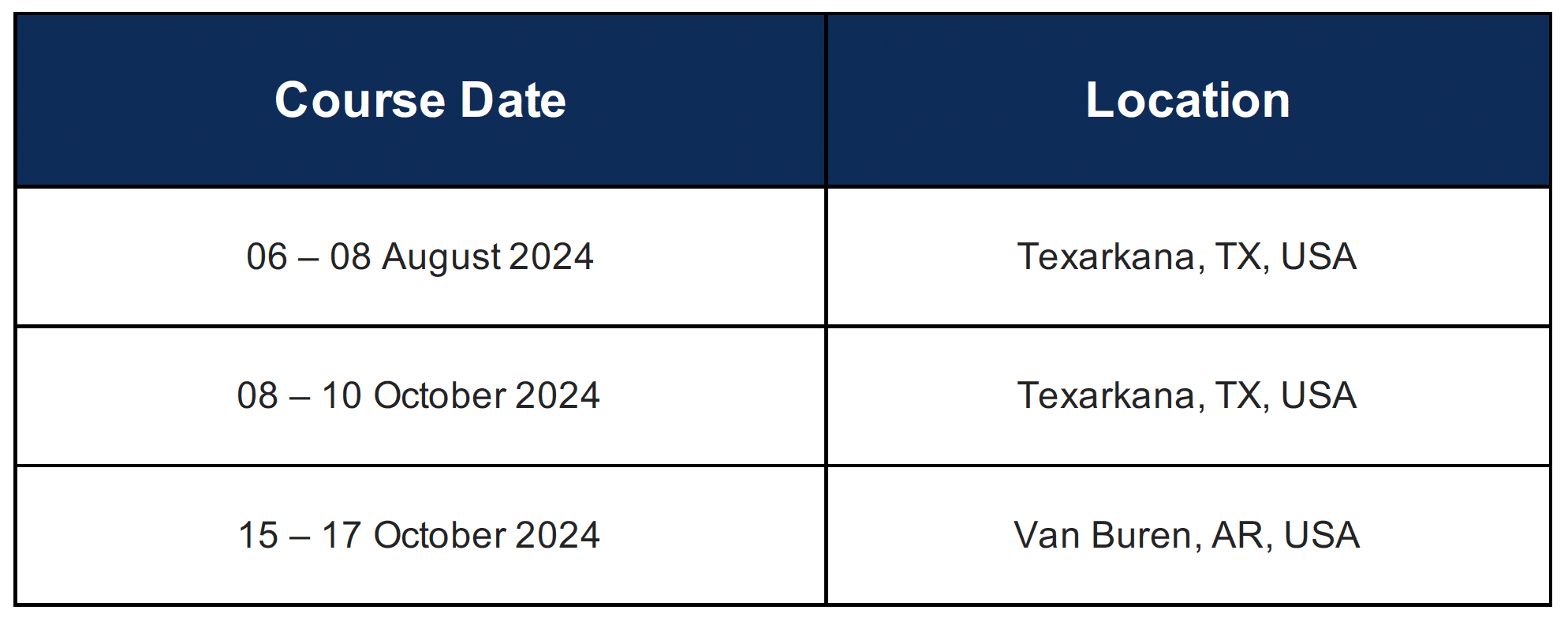

Consider attending one of our training seminars or schedule an on-site class at your convenience.