Our previous article showed dramatic economic incentives for online freeness measurement. So with the impressive numbers in that article, why invest more money in automation?

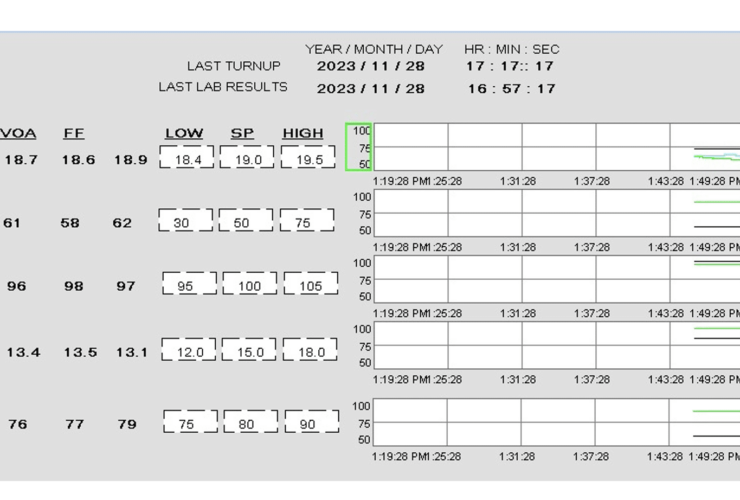

It is practically impossible to monitor every sensor every second and adjust every actuator at the same frequency. That is one of the reasons we have automation. The economic benefits previously shown are theoretically possible, but automation makes them practically probable.

Take the case of increasing production, in which the last article stated a potential $12 Million per year in economic benefit by adding online freeness measurement. Some facilities have seen dramatic improvements in production just by making freeness visible in real-time. However, most of the theoretical benefit comes from automatic control. A safe approximation is that 75% of the $12 million theoretical benefit comes from automation, yielding $9 million annually.

An important consideration is the cost of automation. For a Satron freeness sensor, we do not need advanced control algorithms with expensive licenses. Some believe refining control is complex with many disturbances and non-linear, so a conventional PID control loop cannot achieve optimal refining control.

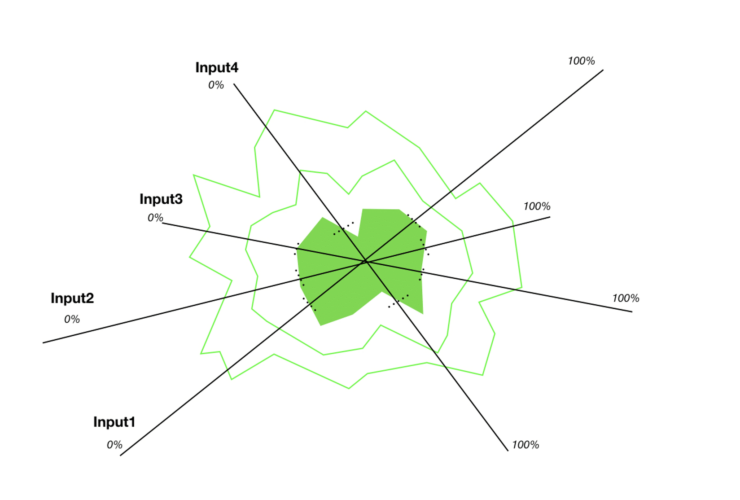

The fact is that while Multivariable Predictive Control is a well-established approach for large-scale optimization, it is overkill for this case. The advantages of implementing refiner control with Satron sensors are:

- No complex and expensive software licenses are required. Instead, a properly configured and maintained PID control loop, a capability built into every control system, is a much more cost-effective option.

- Satron sensors sample every second. Unlike sampling systems which may require up to 30 minutes to detect a persistent change, Satron sensors can detect changes much more quickly. This means the control is much more responsive and can better stabilize when swings occur.

- Since Satron sensors are dual channels, they can also measure consistency. Since consistency is a fundamental property for optimal refiner control, a single Satron sensor can provide all the information for optimal automation of a refiner.

- The PID loop can be more easily maintained without expensive service costs.

Pulmac’s fiber quality and automation experts can provide the best results at the lowest investment cost. Feel free to contact Pulmac to help you understand the return on investment for your mill.