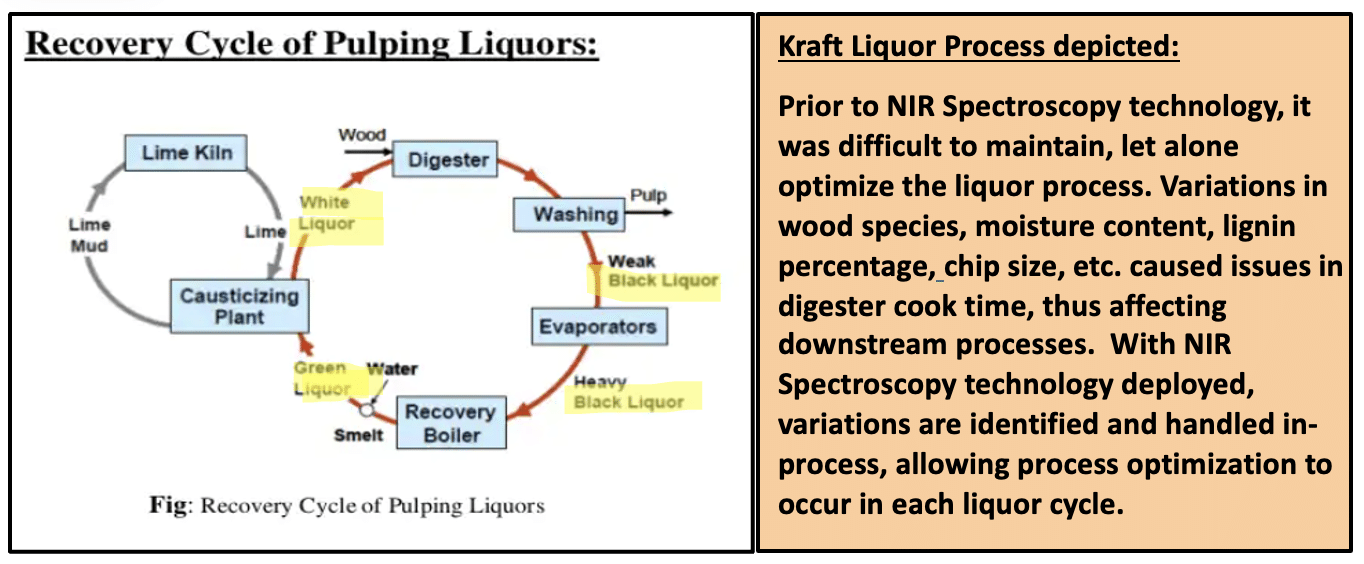

The key to improving the entire liquor cycle is to monitor and optimally control each cycle. These cycles are commonly referred to as the white, black, and then green liquor cycle. See the graphic Recovery Cycle of Pulping Liquors and highlights for each. Prior to the introduction of Near Infrared (NIR) Technology, all systems were set up based on what would be expected for a normal production run. In other words, it was set up on what the mill would normally see and set up as a recipe for that species.

That works well until something changes. For example, variations in wood species, moisture content, lignin percentage, chip size, etc. can cause issues in digester cook time, thus affecting all downstream processes. Prior to NIR technology, an advanced process control was set up based on a grade and would run to those APC limits. But we know there are upsets that affect and impact each liquor cycle.

With Near Infrared (NIR) technology, it can and does automatically read through that pulp slurry to tell you that there are incomplete chemical reactions and can adjust that automatically. In case you were wondering, the Red in RedEye is a play on the words of Near Infrared.

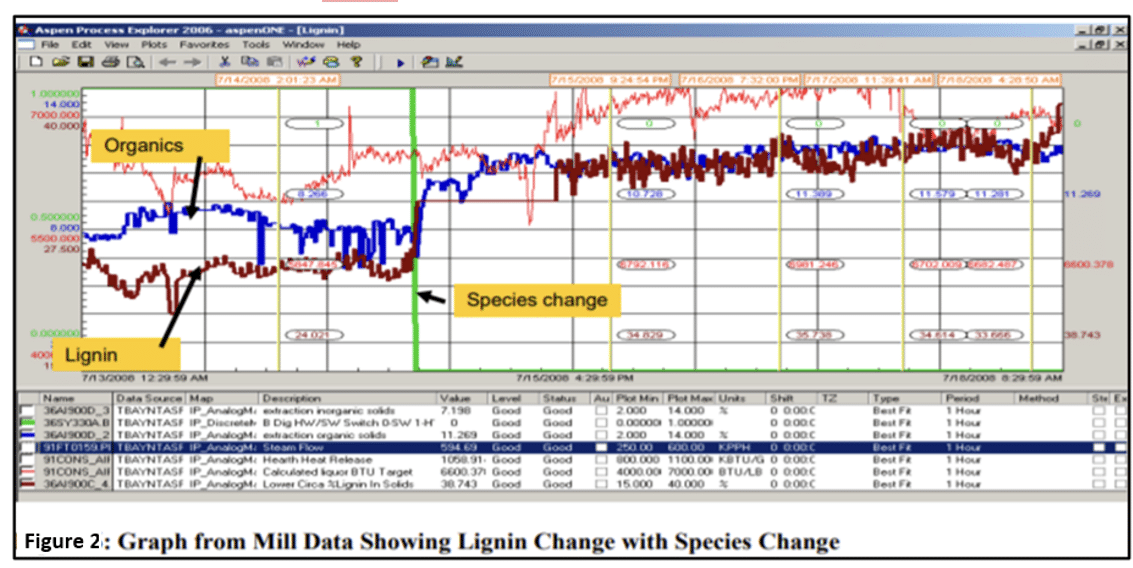

In Figure 2, we see where the PulpEye instrument, RedEye™, has detected a wood species change and its corresponding level of lignin. Recall that lignin is a measurement of how well the digester removed lignin, the glue that holds the pulp fibers together. That is what the Kappa Number measures.

Think of each liquor cycle that has several variables that need to be measured and ultimately controlled. This can now be completed using NIR technology. Just how effective are these NIR Measurements? NIR spectroscopy can effectively measure Kraft liquor properties with an accuracy of 0.99 or better correlation coefficient with the laboratory. That allows each liquor cycle to now be controlled independently and optimized for the overall liquor process.

Key properties that are measured for each liquor cycle:

White Liquor Properties

Effective Alkali (EA)

Active Alkali (AA)

Causticizing Efficiency (CE)

Sodium Carbonate

Sodium Sulfide

Sodium Sulfate

Sodium Thiosulfate

Black Liquor Properties

Residual Effective Alkali (REA)

Green Liquor Clarified and Unclarified

Total Titratable Alkali (TTA)

Effective Alkali (EA)

Active Alkali (AA)

Sodium Carbonate

Sodium Sulfide

Sodium Sulfate

Sodium Thiosulfate

Reduction Efficiency (RE)

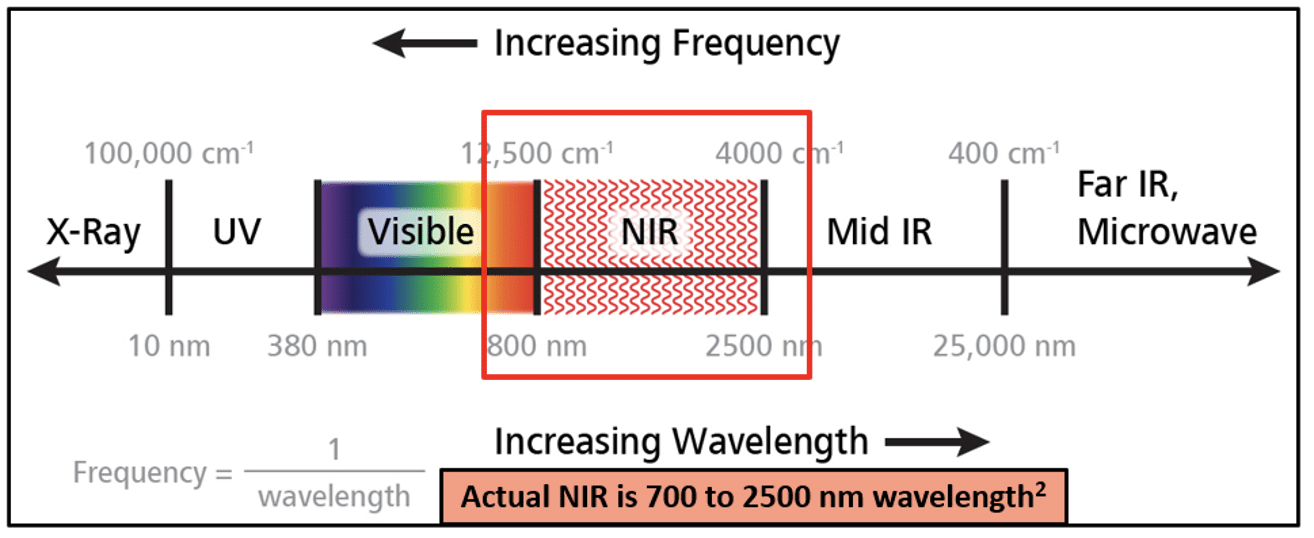

NIR Wavelengths

What are the NIR Wavelengths associated with measuring these various chemical compounds? Near Infrared is approximately 700 through 2,500 nm (nanometers) in length.

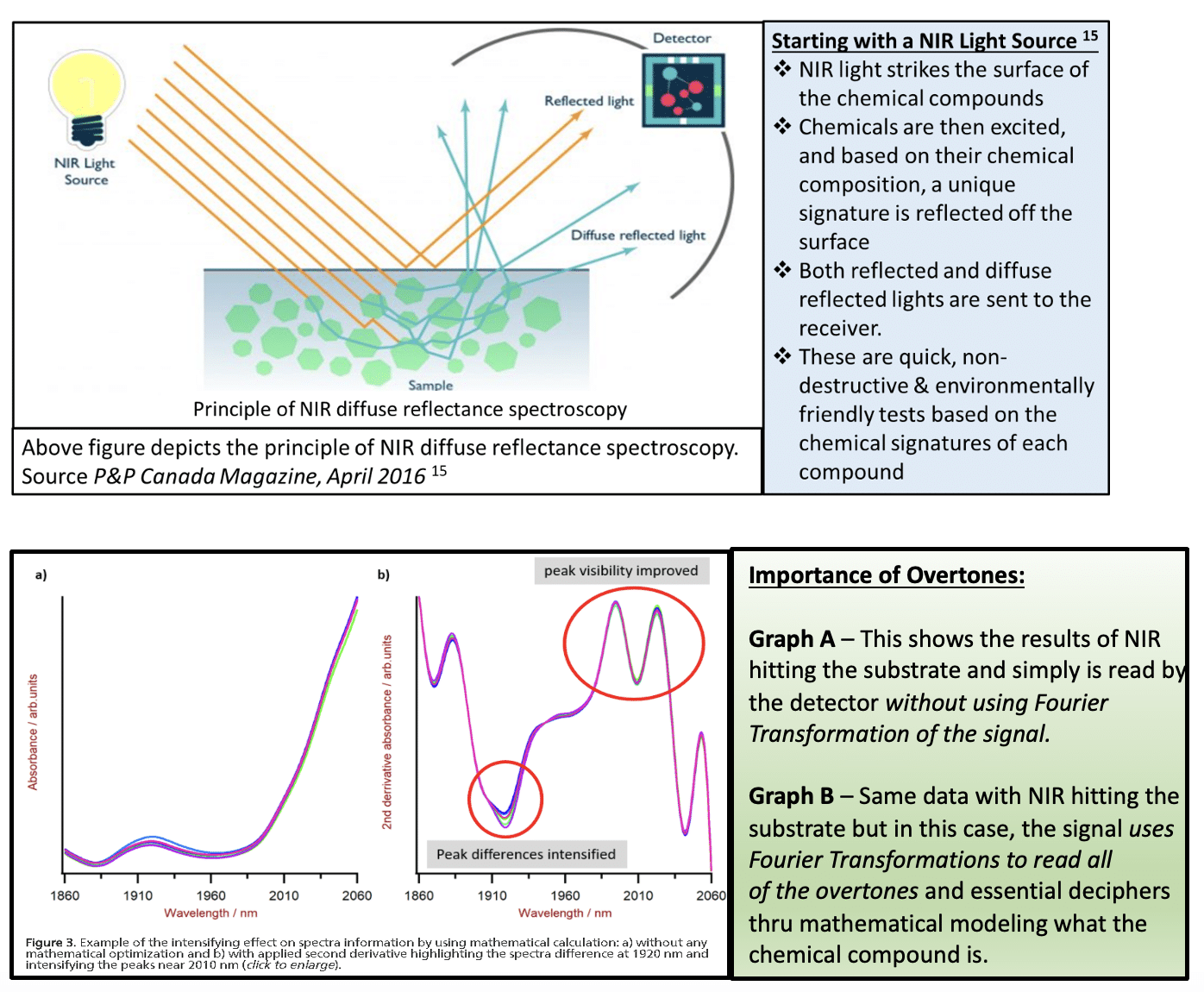

How does NIR detect various chemical compounds?

It’s through the absorption of near-infrared light, like that of mid-infrared light, that is based on the vibration of the material. Near-infrared light absorption is weaker in intensity as compared with mid-infrared light absorption, since near-infrared light absorption is based on overtones and combined tones in the mid-infrared light region but none-the-less provides an effective means to ID compounds.

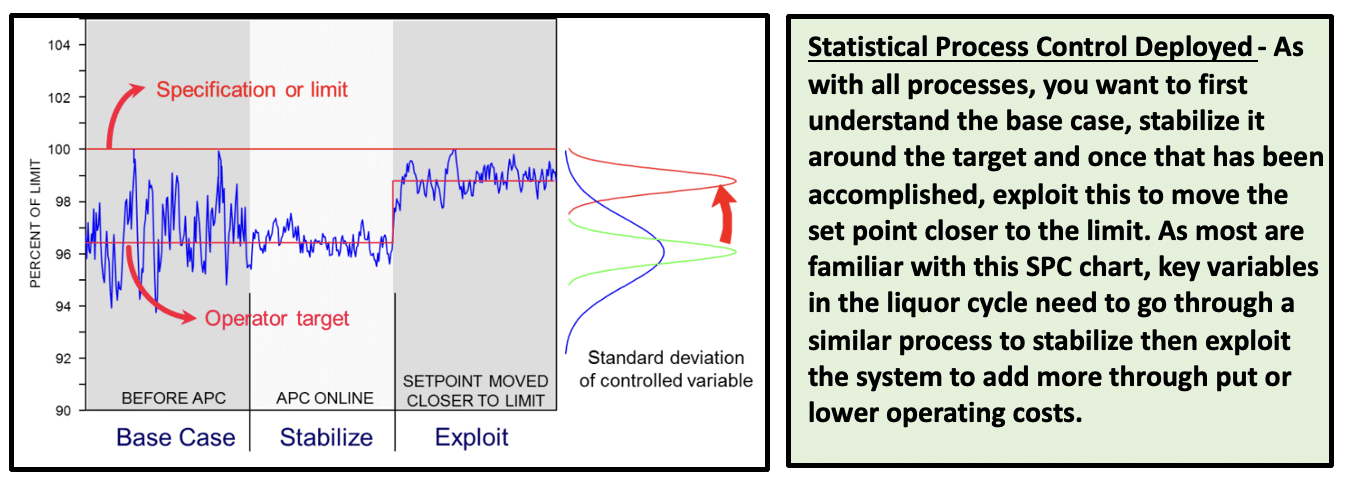

Mill personnel recognize that to achieve overall liquor efficiency, each liquor cycle has to be in good statistical control.

All liquor cycles (White – Black – Green) have critically important processes that must be measured and controlled. And in each liquor cycle, this is accomplished by using NIR technology to measure and control the important variables for each. And yes, these are controlled to within 99% R2 value.

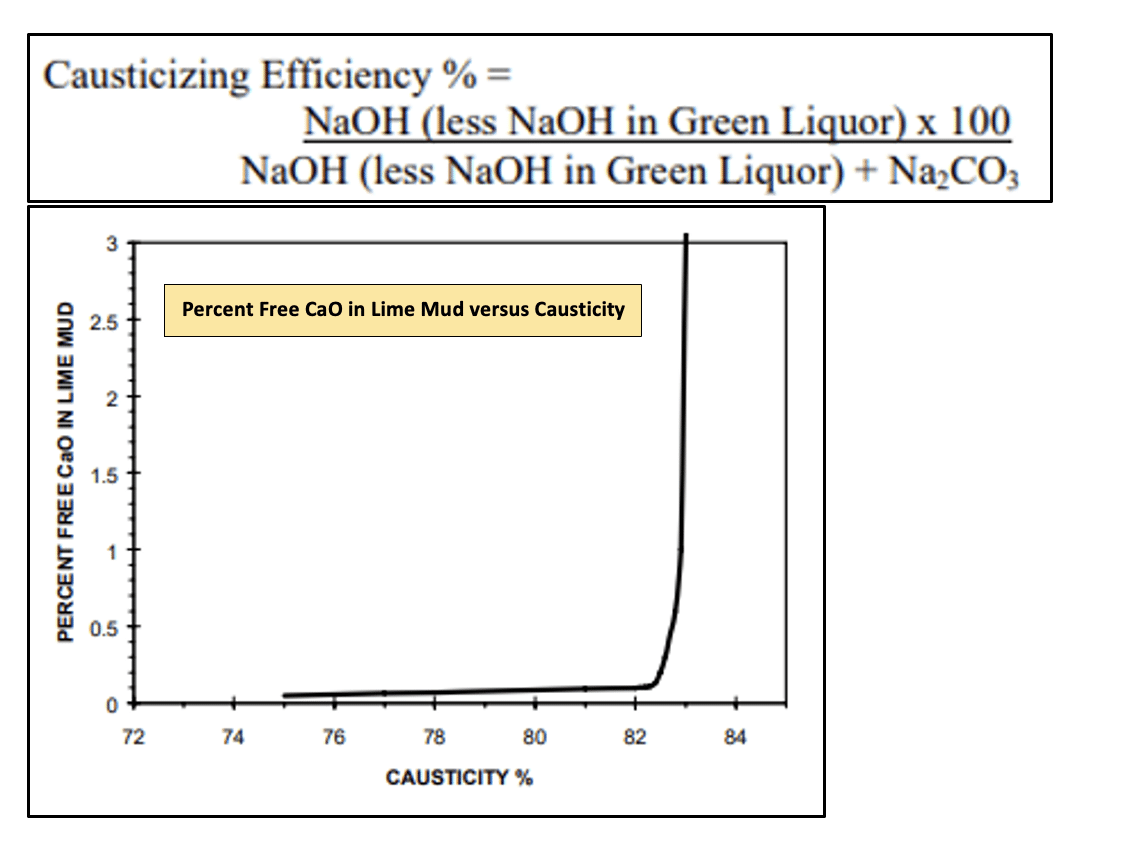

Causticizing Efficiency (CE): Improving the Kraft Liquor Cycle (Using PulpEye’s RedEye)

Measuring causticizing efficiency is a key to understanding how well the chemical recovery process is working compared to a theoretical 82%/ 83%. By using just one measurement at the end of the liquor cycle, Causticizing Efficiency (CE), this one variable provides a yardstick on how well the entire liquor cycle is running. In other words, Causticizing Efficiency (CE) allows for a quick but effective means to determine how well the overall liquor cycle is being controlled.

Most mills run around 75% CE and the theoretical max CE is 82 to 83%. With a RedEye™, it is routinely possible to achieve an 80% CE. So, what is the value to move a mill’s CE from 75% to 80%?

RedEye™ Example

Here is an example of a financial instrument to determine what the range of IRR is possible by deploying a RedEye™ in your facility:

IRR (%) = (Total Annualized EBITDA) * 0.72/ (Total Installed Cost)

Assumptions: Raise CE from 75% to 80%

Each CE% is worth $250K. So, raising it from 75% to 80% CE = $250K* 5 pts = $1,250K/year

Total EBITDA (Total Annual Cash Flow Improvement) = $1,250K/year

0.72 = Removes Taxes, Interest, Depreciation

Total Installed Cost = $1,000K (Installed cost of the RedEye™ for $800K plus $200K installation)

IRR (%) = (EBITDA) * 0.72/ (Total Installed Cost)

= $1,250K * 0.72 / $1,000K

= 90% IRR

Yes, the return of 90% IRR is high but is indeed possible. The key assumption is the $250K/1% CE. This of course will vary depending on the size and production rate of your facility. PulpEye’s RedEye™ technology on Near Infrared (NIR) comes from and is licensed through FP Innovations. This is the same NIR technology available by others in this field.