A common challenge in making tissue is transitioning between grades. During these transitions, it can take a long time to go from first-quality production on the current grade to first-quality on the next grade. During this transition, the process can be in a bit of chaos before settling into the next grade. This chaotic transition can lead to sheet breaks and other sources of lost time. In terms of Overall Equipment Effectiveness (OEE), this can mean a loss of efficiency from not meeting quality targets (off-spec production) or not yielding any production (such as sheet breaks).

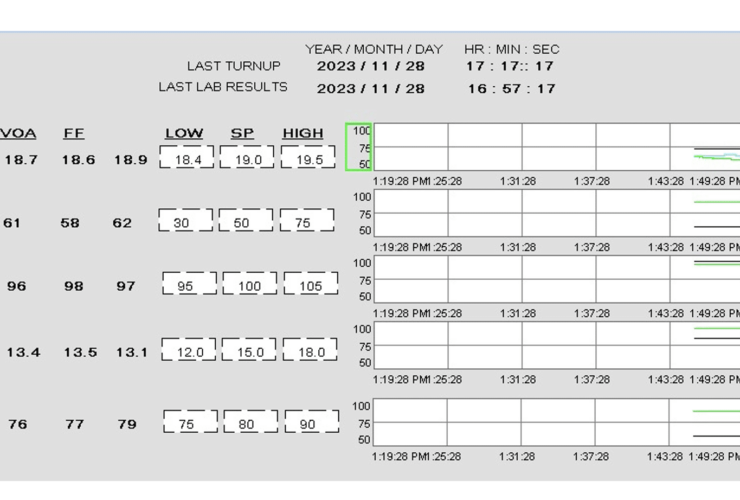

In data analytics, a technique called centerlining can help. This can help ensure the process variables for each grade are known and dialed in when going to each grade.

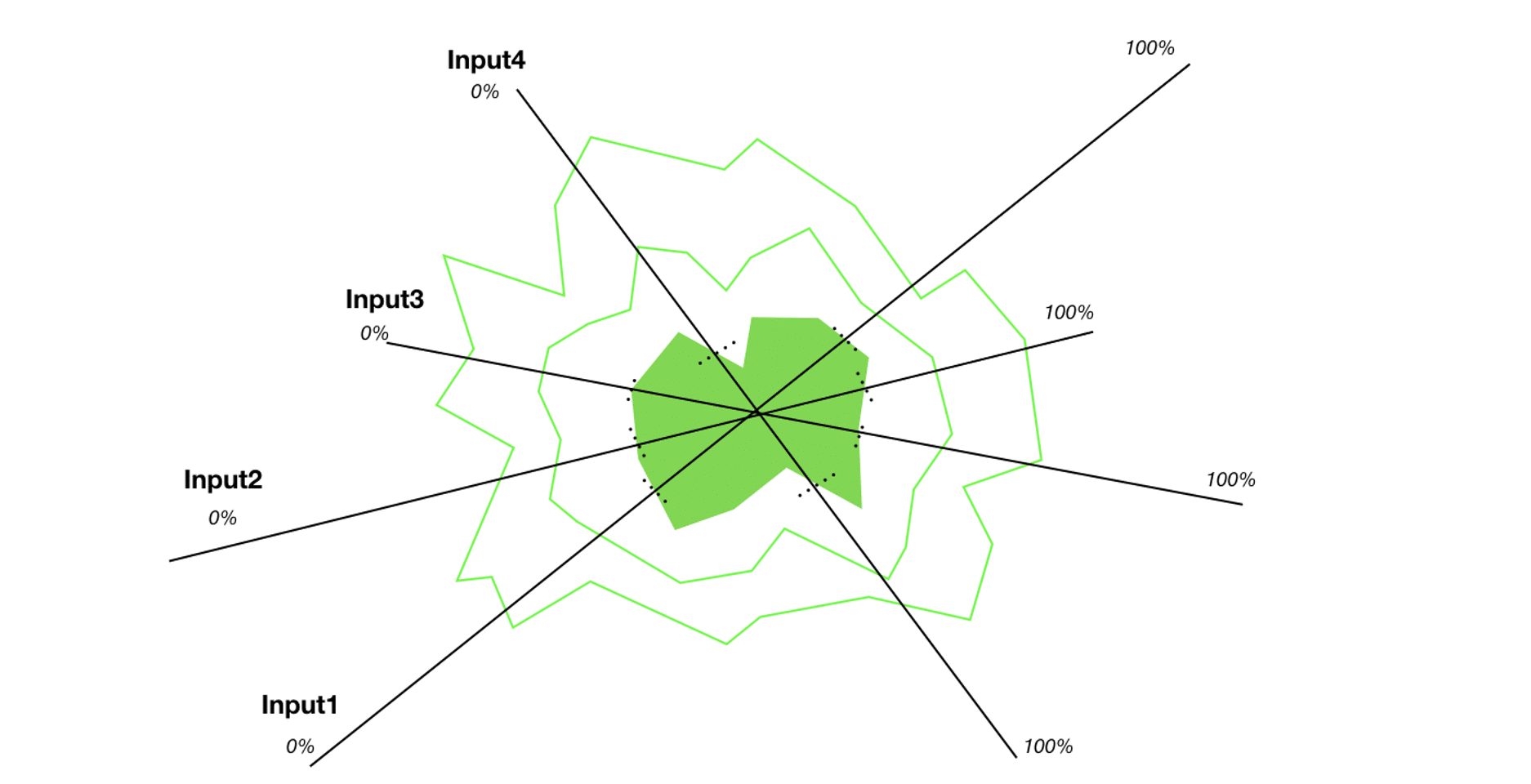

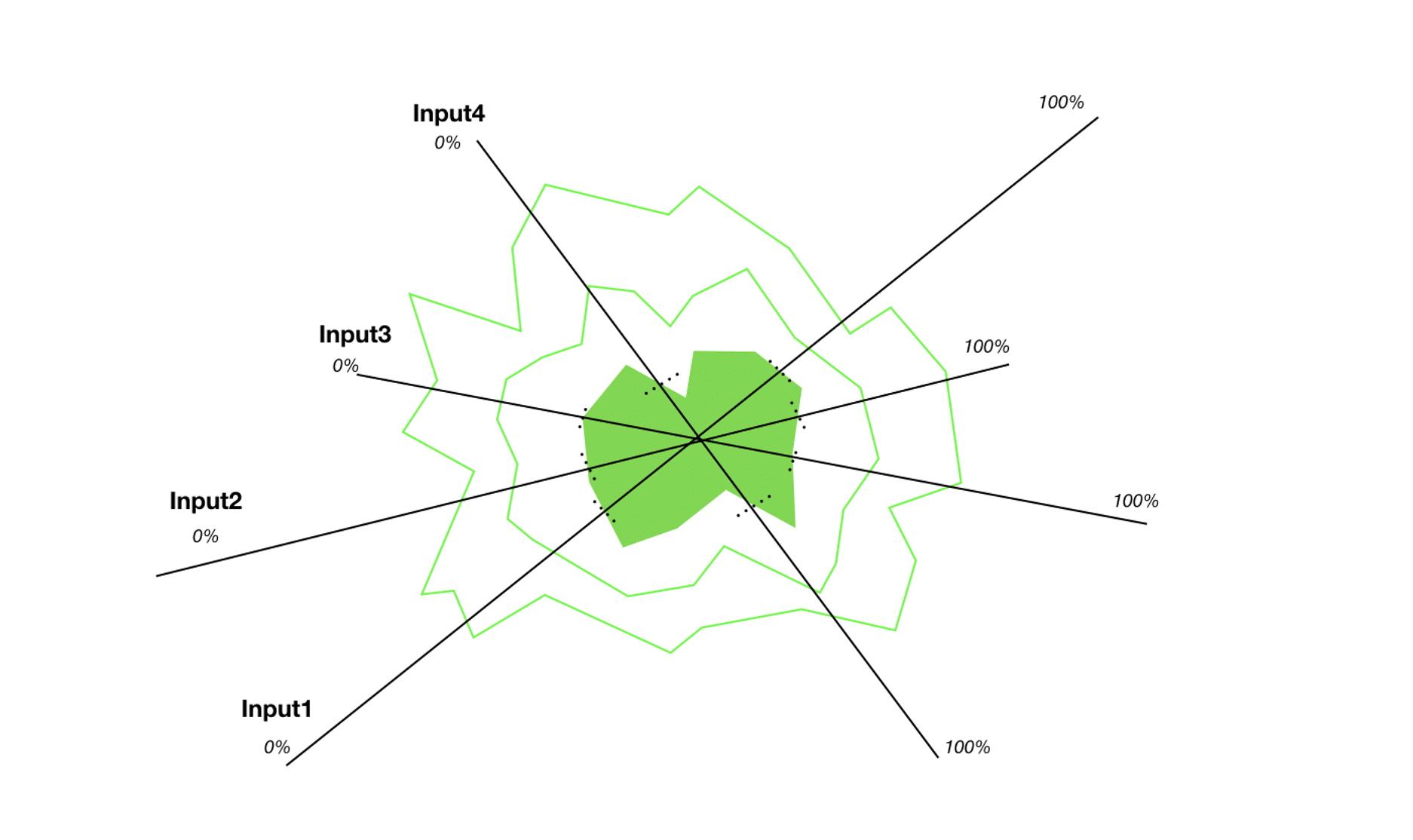

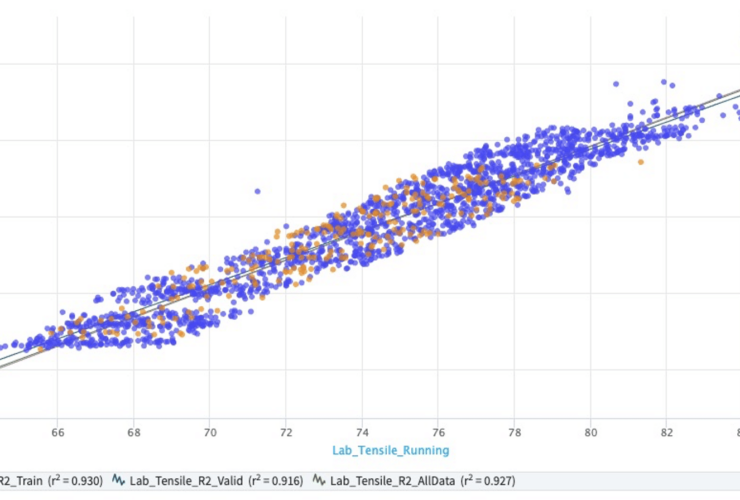

To ensure there is a common understanding, the objective of centerlining is to find the “operative envelope” for the best operation. The “operative envelope” is the range of inputs to the process that deliver the best outputs. The inputs are those control loops that affect the quality or efficiency of production. The outputs are quality measurements that are typically made in the testing lab and key performance indexes (KPIs) such as the number of sheet breaks per reel or uptime.

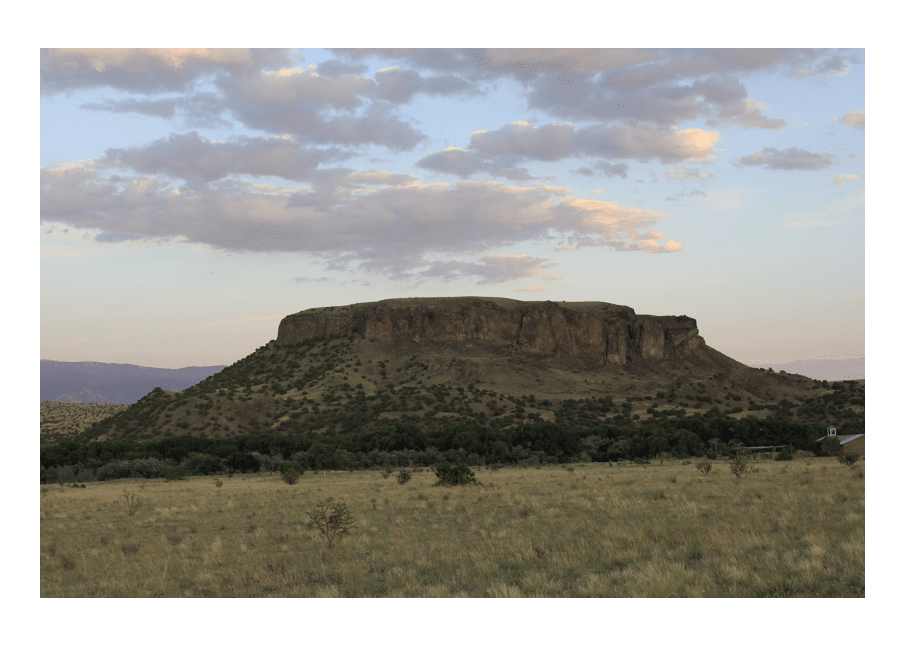

It can be visualized as a mesa where the objective is to get to the top performance.

Looking down from above (the bird’s eye view), the contours show a narrowing area as you ascend. By setting inputs within a narrower range the peak performance is achieved.

Using historical process data, centerlining finds the sweet spot for each grade so that the setpoints are dialed in when making a grade change.

It is understood that all paper machines have quality control systems (QCS) that measure weight and moisture and may have automated grade change capability for those setpoints and calibration curves in the sensors. However, there are many control loops outside of weight and moisture control that affect quality and operations. These are the grade-dependent setpoints that can be obtained from centerlining.

Typical applications of centerlining on tissue machines can yield a 3% improvement in OEE, which can have a huge cumulative impact on the bottom line.

Pulmac DataSolve is a service that can apply the powerful capabilities of Seeq to produce a centerline application that the mill can use. DataSolve can provide monthly data analytics service and support to ensure your process data does not go to a digital landfill. Your data can be turned into gold with the help of Pulmac and Seeq through the DataSolve service.

Let Pulmac be your partner to improve the OEE of your tissue mill. Contact our team today.