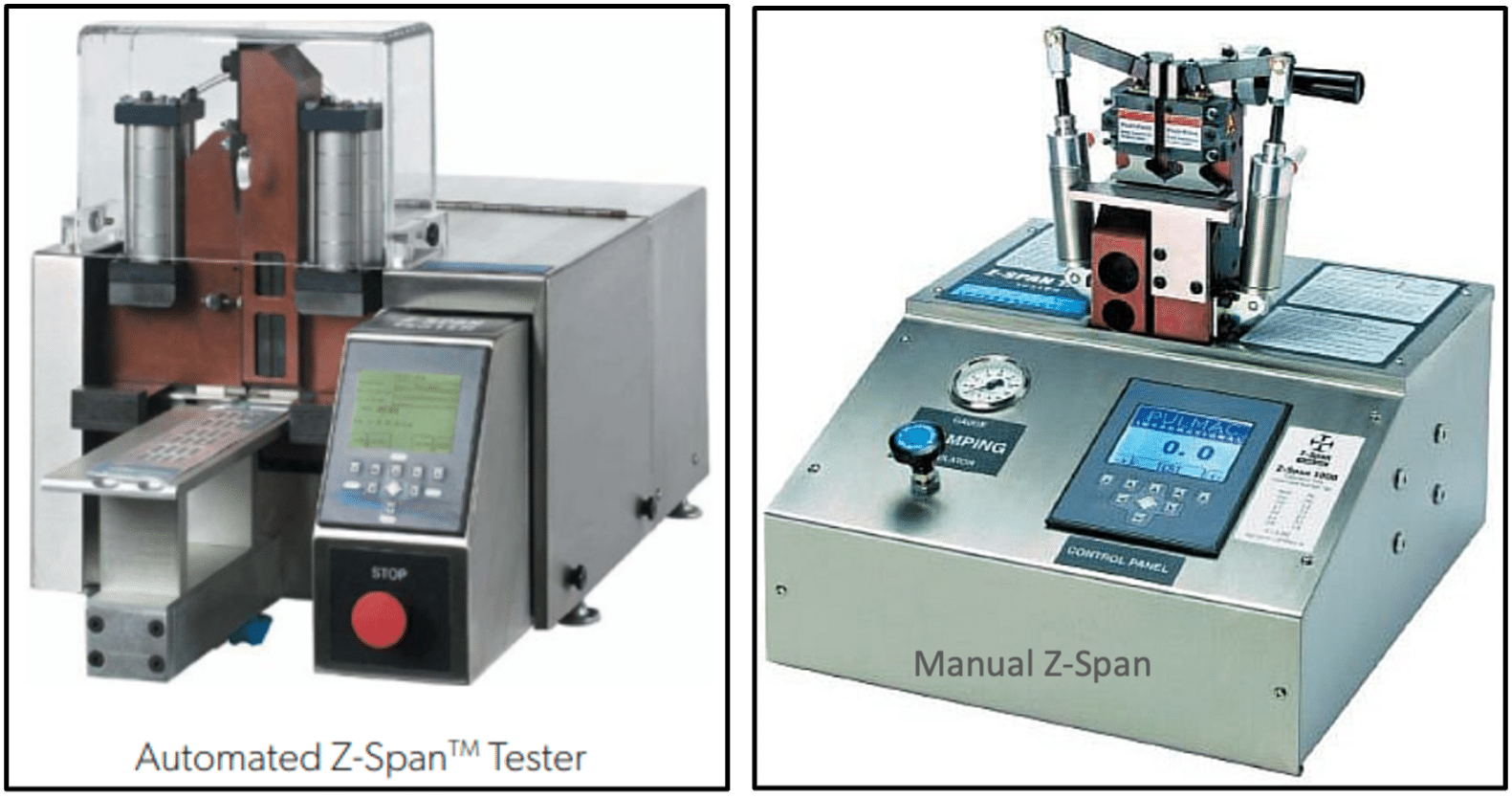

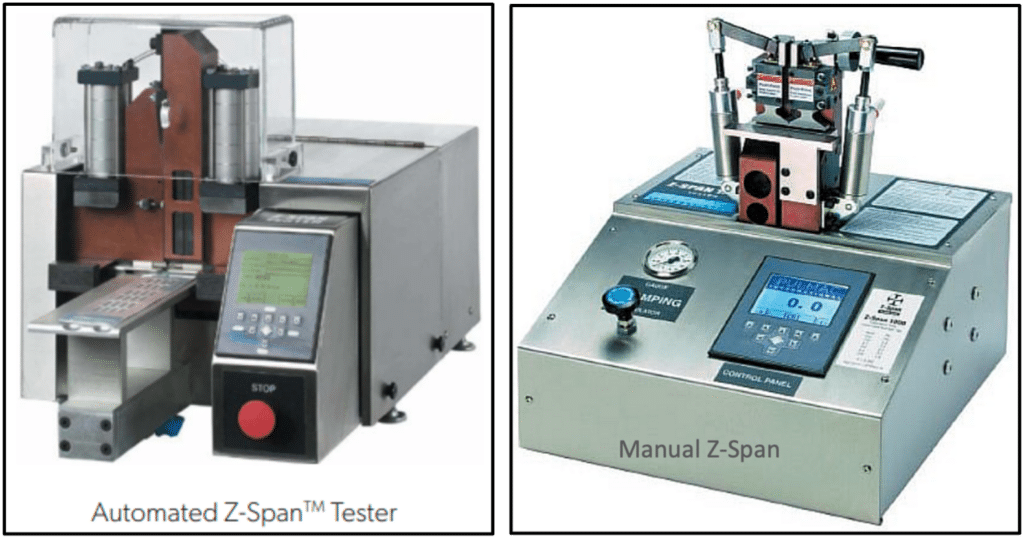

This week’s post focuses on an important heritage piece of equipment from Pulmac’s Systems line of pulp & paper instruments, the Zero-Span™ Tester. This comes in two versions: an automated version and a manual version. Typically, these units are referred to as a Z-Span™ Tester.

Quick Overview of a Z-SpanTM Tester

The key benefit of a Z-Span™ Tester is that it defines the pulp’s fiber properties based on where the pulp samples are drawn from. Specifically, the three properties tested are fiber strength (FS), fiber length (L), and bonding potential (B). Zero-span fiber quality tester permits gathering rapid and repeatable information on the fundamental pulp quality characteristics of fiber strength, fiber length, and bonding potential of the pulp fibers. This information can be used to monitor the effects on your pulp quality of changing wood supply, pulping conditions, bleaching, refining, and blending operations and predict subsequent performance on a paper machine.

Once understood, the Automated Z-Span™ testing will provide significant data to the pulping, bleaching, and paper machine operations. Specifically, monitoring the fiber strength (FS) number aids in evaluating the effect on the tensile strength of the fiber to different cooking conditions (temperature, liquor addition, liquor removal), bleaching (pH, chemical concentration), refining (fiber straightening, internal bonding enhancement). The fiber length (L) number alerts operations when chip quality causes fiber length to depart from normal variation, i.e., hardwood contamination of softwood chips, over-refining, etc. The fiber bond (B) number is sensitive to major changes in pulping, bleaching, and refining processes. With these three fiber quality indicators, operations will be informed in a timely manner of changes in strength properties produced by changes in operating conditions. Measurement of stage-by-stage strength loss through the mill will also give operations the rapid means necessary to isolate and remedy, as required, sources of strength loss or gain.

This older drawing intends to provide a visual for each fiber property measured. Fiber strength (FS) would be for zero span dry and wet strength tensile, fiber length (L) measures the average fiber length and fiber bonding (B).

The Z-Span Tester is controlled by an embedded controller with a user interface presenting both touch screen and “button” controls. Data is sent to a PC via a serial cable with custom-loaded software for further handling and analysis.

The Automated Z-Span Tester brings pulp quality measurement out from the laboratory and into operations on a near real-time basis. The tester produces 24 individual test results per five-minute test sequence, 24 hours a day, seven days a week. This enables rapidly accumulating and maintaining a statistically significant and operationally meaningful database. With these three fiber properties, whether from the manual or automated Z-Span™ tester, test results can alert mill monitors to creeping process changes before pulp quality deteriorates beyond acceptable limits.

Performing Automated Z-SpanTM Tests

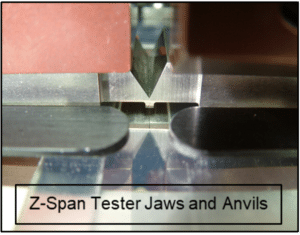

The Automated Z-Span Tester is a single unit with X-Y sample movement, pneumatics, electronics, HMI control module, and the zero and short span tensile main assembly. Pulp samples are prepared, where 63.5mm in diameter test sheets are developed for testing. Test sheets are then brought to the Z-Span Tester. These test sheets need to be weighed to obtain their relative basis weight. (Depending on environmental conditions, a hygroscopic standard can be employed.) Weighed sheets are then loaded onto the Z-SpanTM Tester feed tray, rewetted or left dry, and then the appropriate test is activated.

Within 5 minutes, 24 individual “breaks” are performed, and average test data is displayed. Alternatively, paper from the reel of the paper machine can be tested by preparing test strips oriented in the machine and cross directions. The default RUN TEST screen is pre-set by the system manager from one of these options:

- TEST Fiber Strength (FS) for 24 zero-span tensile tests

- TEST Fiber Strength (FS) and Fiber Length (L) for 12 zero and 12 short-span tensile tests

- TEST FS-L-B for 8 short dry, 8 short wet, and 8 zero span tensile tests.

Direct improvements to your productivity can include reducing downgraded pulp, penalty payments, and warehousing costs, all the while improving communication links with pulp users. Increased profitability through troubleshooting, optimization, and monitoring are key attributes that set this equipment apart from other automated advances in the industry at a fraction of the cost.

Advantages of the Automated Z-SpanTM Tester

Fiber Strength (FS) Number

The FS number is an index of average fiber strength expressed in Newtons per cm (N/cm) at standard basis weight. Test sheets are re-wet to eliminate inter and intra-fibre bonds. The test sheets are clamped between two jaws in direct contact (zero span). All load transmitted between these jaws is carried by only the fibers clamped by both jaws. The failure load will equal the number of clamped fibers multiplied by their average strength. Since this number remains constant in standard basis weight test sheets, any changes in the zero-span failure load will reflect changes in the average strength of the fibers. This wet zero-span test result is the FS number. Any changes to it indicate changing average fiber strength caused by mechanical degradation of the fiber walls due to chemical or mechanical actions of pulping sequences.

Fiber Length (L) Number

If the jaws are separated by 0.4 mm, then some securely clamped fibers at zero span will not bridge the gap and cannot be clamped by both jaws. As a result, fewer fibers will transmit load, and the wet tensile failure load will necessarily decline. The ratio of the wet 0.4 mm span test to the wet zero span test represents the fraction of fibers active at zero span, which are still active at a gap of 0.4 mm. This fraction, the L number, is a proportional index of average fiber length. Changes in the L number will occur due to changing average fiber length.

Fiber Bond (B) Number

If the wet 0.4 mm short-span test is compared to the dry short-span test, the increased ability to transmit load across a bonded fiber structure will be noted. Inter and intra-fiber bonding allows loading to be transmitted between fibers and across zones of degradation on individual fiber walls so that all fibers can carry load independently of whether or not they cross the short span. The ratio of the dry 0.4 mm span test to the wet 0.4 mm span test will be proportional to bonding strength. This ratio is called the B number; changes indicate changing bonding potential.

To learn more contact us or download a product brochure below: